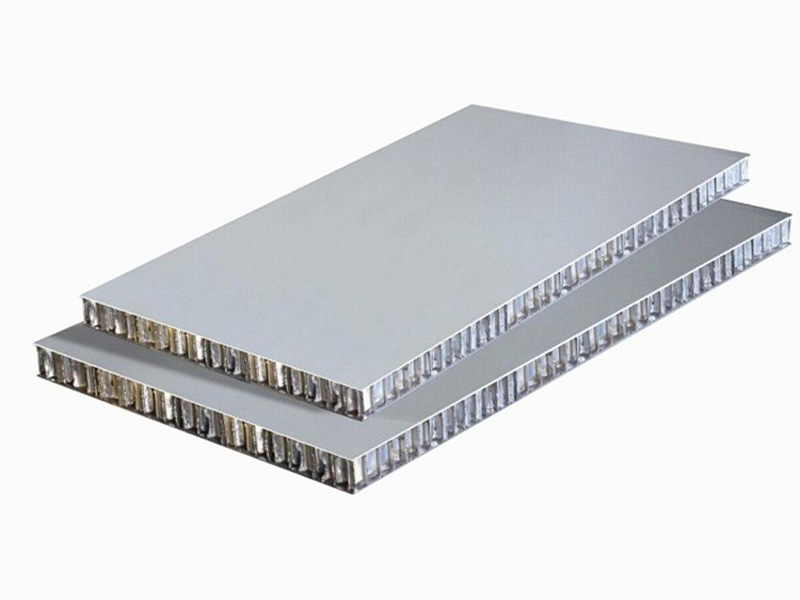

In many ways, aluminum is the perfect metal. It is strong, light, heat-resistant and corrosion-resistant. It is also a good conductor. Most importantly, it is rich and cheap.

Aluminum is also the most abundant metal in the earth’s crust and the third richest element after oxygen and silicon. However, it was not until 1809 that the English chemist Sir Humphrey David formally identified and named it.

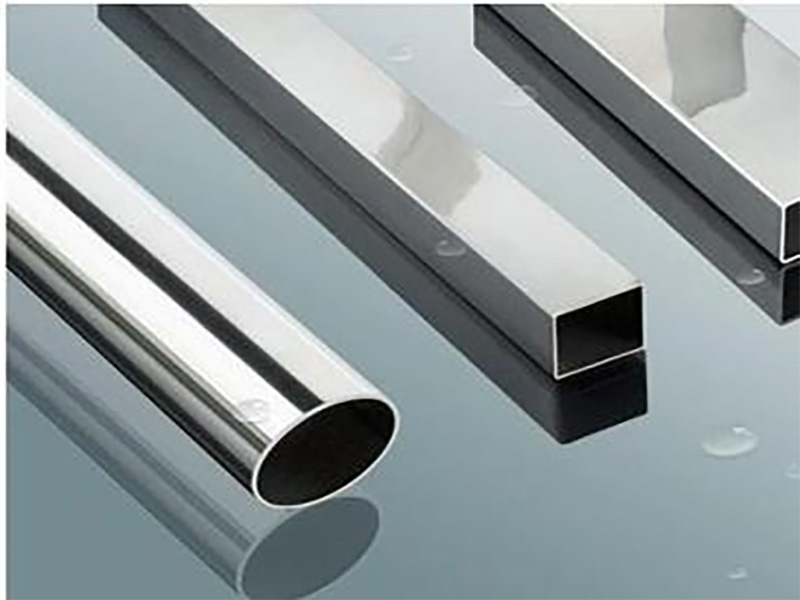

Today, aluminum is the most commonly used metal in the world except steel. From the cars we drive to food packaging, aluminum is an important part of almost every part of our life.

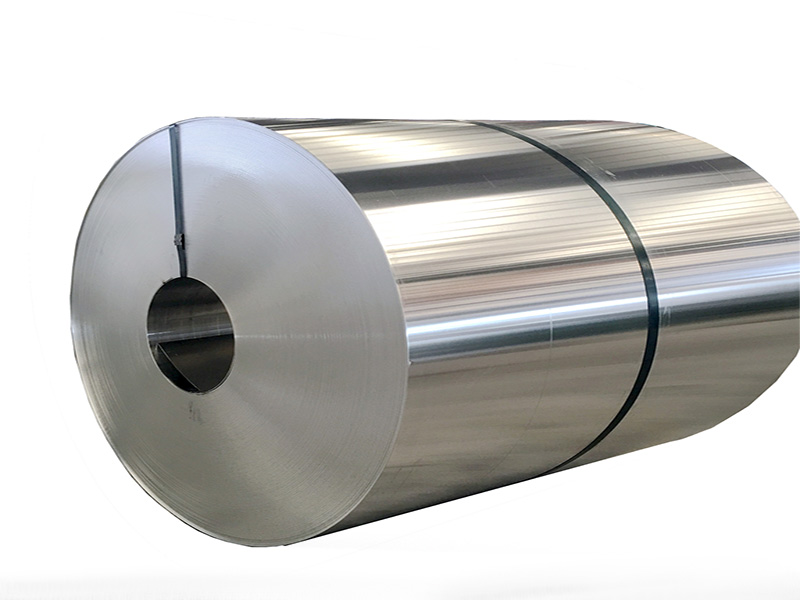

When aluminum combines with other metals to form aluminum alloy, it is most widely used. The alloying process improves the properties of aluminum to adapt to various applications.

The first stage in making aluminium is locating the aluminium ore.

Aluminum tends to combine with other elements and rarely exists in the form of pure metal in nature. Aluminum compounds are found in most common rock types, including clay, slate, shale, granite and anorthosite.

The most important bauxite is bauxite, a rock containing about 52% alumina, with impurities such as iron oxide, silicon dioxide and titanium dioxide. Bauxite is widely found in surface or near surface deposits in many parts of the world, including Europe, Asia, Australia and South America.

Geologists determine the location of bauxite by sampling and drilling. Once a mineral deposit is found, it is mined in the open air. The bauxite was blown loose and the bauxite was extracted with a shovel or rope.

90% of the mined bauxite is made into alumina and then melted into aluminum. The remaining 10% is used for other purposes, including the manufacture of abrasives, furnace linings and proppants for the petroleum industry. It takes 4 tons of high-quality bauxite to produce 2 tons of alumina, while alumina can produce 1 ton of aluminum.

Bauxite is refined by Bayer process, which was first developed by Carl Joseph Bayer in 1888. Bayer process has four steps: digestion, clarification, precipitation and calcination.

Digestion

Bauxite is ground, mixed with caustic soda and pumped into a pressure tank where it is steam heated and pressurized. This makes caustic soda react with aluminum compounds in bauxite to form sodium aluminate solution. Unwanted impurities are left in the so-called red mud.

clarify

Next, the sodium aluminate solution passes through the blowing tank, where the pressure is reduced to atmospheric pressure. Red mud can be removed by using clarifier and cloth filter. The clarified solution is cooled in a heat exchanger and then pumped into a high silo.

precipitation

Aluminum hydroxide seed crystal is added to sodium aluminate solution to cause precipitation. In this process, aluminum becomes a solid. This results in large aluminum crystals being filtered and washed to remove water and other impurities.

calcination

Now aluminum hydroxide crystals need to be calcined, which is a heat treatment process to control the air supply. A rotary kiln is used to heat the crystal to a temperature exceeding 960 ° C to remove any remaining impurities, leaving a fine white powder called alumina or alumina.

Smelting is the process of extracting aluminum from alumina. This is achieved through the hall-h é roult process, which was invented by Charles Martin hall and Paul h é roult in 1886.

The smelting process is carried out in a steel reduction tank filled with molten electrolyte, in which the carbon anode is used to pass current through the electrolyte. Alumina is then added to the molten surface. The current deposits molten aluminum that can be collected and siphoned.

The molten aluminum is then poured into the mold to form a casting ingot. At this stage, its purity is 99.8%. Now, it can be further refined to produce ultra pure aluminum or used in alloys with other metals.

High purity ultra pure aluminum (99.99%) is soft and has insufficient tensile strength. However, it is corrosion resistant and excellent conductor. Ultra pure aluminum is used in chemical equipment, electronic components and gasoline manufacturing.

High purity ultra pure aluminum (99.99%) is soft and has insufficient tensile strength. However, it is corrosion resistant and excellent conductor. Ultra pure aluminum is used in the manufacture of chemical equipment, electronic components and gasoline.

Aluminum can be recycled indefinitely without losing its quality. This makes it one of the most environmentally friendly metals on earth. It is incredible that most of the aluminum once produced is still in use today.

For Further Details,Please Feel Free To Contact Us: