Inconel 718 alloy, a precipitation-hardened nickel-chromium-iron alloy containing niobium and molybdenum, exhibits high strength, good toughness, and corrosion resistance in both high and low-temperature environments, particularly at 700℃. It can be supplied in a solution-treated or precipitation-hardened state.

Characteristics

1. Ease of machinability

2. High tensile strength, fatigue strength, creep strength, and fracture strength at 700℃

3. High oxidation resistance at 1000℃

4. Stable chemical properties at low temperatures

5. Excellent weldability

Corrosion Resistance

Inconel 718 alloy demonstrates outstanding resistance to stress corrosion cracking and pitting corrosion in both high and low-temperature environments. Its oxidation resistance at high temperatures is particularly remarkable.

Applications

Due to its high-temperature strength, excellent corrosion resistance, and machinability at 700℃, Inconel 718 alloy finds wide application in various demanding fields:

1. Gas turbines

2. Liquid-fueled rockets

3. Cryogenic engineering

4. Acidic environments

5. Nuclear engineering.

In conclusion, Inconel 718 alloy stands out for its exceptional properties and versatile applications in challenging environments, making it a sought-after material in industries requiring high performance and reliability.

By leveraging the unique qualities of Inconel 718 alloy, industries can achieve enhanced performance and durability in their applications, ensuring reliable operation under extreme conditions.

For more information on Inconel 718 alloy and its applications, consult with industry experts to explore the full potential of this advanced material.

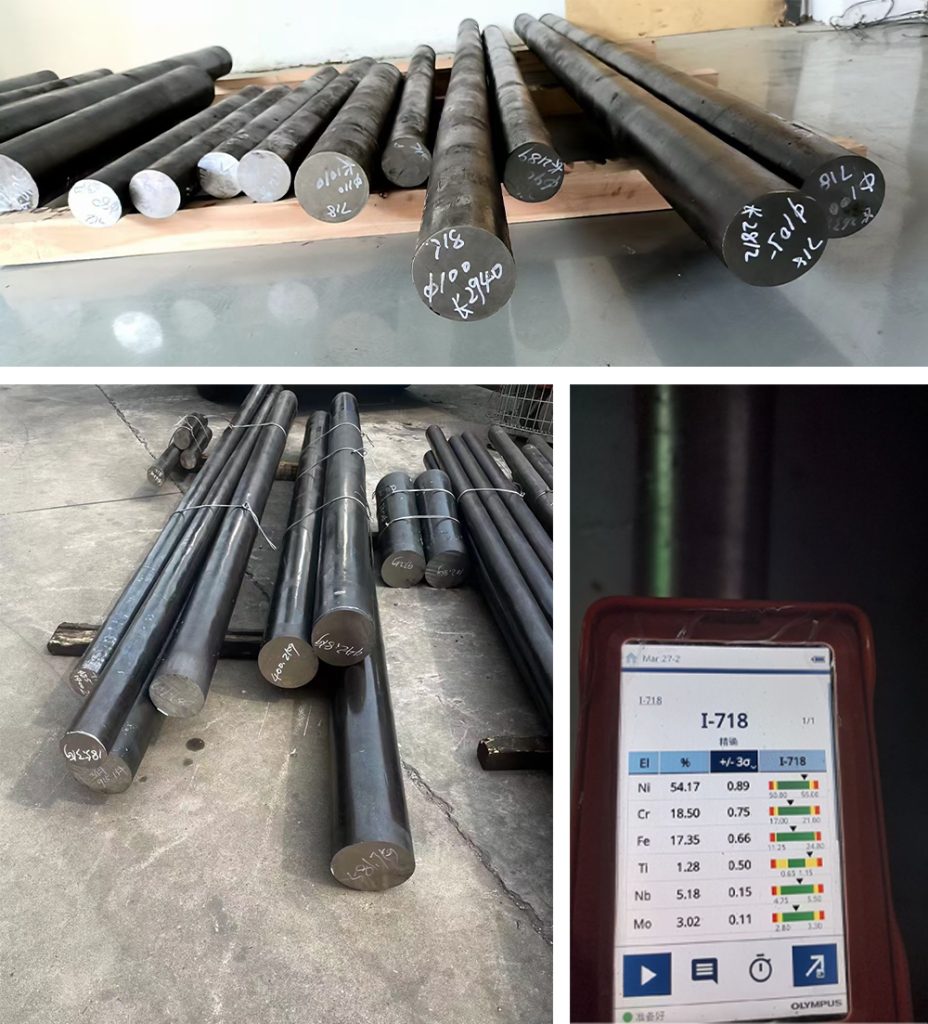

Shandong Baowu Steel Group supplies Inconel 718 round bars in various lengths and diameters. We also have a variety of other steel products to meet each customer’s usage requirements and specifications. Inquiries are welcome.

For Further Details,Please Feel Free To Contact Us: