Metal materials belong to metallurgical products, engaged in the production of metal materials, ordering, transportation, use, storage and inspection must be in accordance with the unified technical standards – metallurgical product standards. Personnel engaged in metal materials must master the relevant content of the standard.

The standard of metallurgical products used in Our country is the national standard (code for “GB” GB”), the ministry standard (ministry of metallurgical industry standard “YB”, the ministry of Machinery standard “JB”, etc.) enterprise standard three.

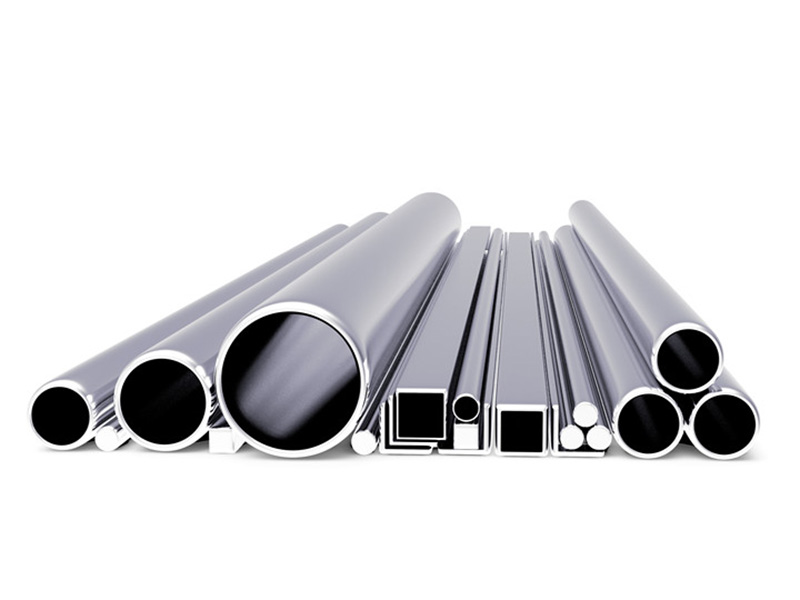

According to the type, shape, size, accuracy and corrosion resistance of metal materials.

1. Bulk: namely unpacked, spindles, blocks (not afraid of corrosion, not valuable), large steel (large steel, thick steel plate, rail), pig iron, etc.

2. Bundle: refers to small size, corrosion has little influence on use, such as small and medium-sized steel, pipe steel, wire, thin plate, etc.

3. Cask (drum) : refers to anticorrosive, small and thin products, such as tinplate, silicon steel sheet, magnesium ingot, etc.

4. Axis: finger wire, wire rope, steel strand, etc.

Check whether the package is complete or not.

The mark is the mark that distinguishes the material and specification of the material, and mainly describes the supplier’s name, brand number, inspection batch number, specification, size, grade, net weight and so on. Mark has;

5. Color: on the end face of metal materials, the end is coated with various colors of paint, mainly used for steel, pig iron, nonferrous raw materials, etc.

6. Printing: the method of stamping or painting on the specified part of metal material (end face, end part), indicating the material’s brand number, specification, standard number, etc. Mainly used for medium – thick plate, profile, non-ferrous material, etc.

7. Listing: bale, box, shaft and other metal materials are listed on the outside to indicate their brand number, size, weight, standard number, supplier and so on.

The marks of metal materials should be carefully identified during inspection and properly protected in the process of transportation and storage.

Specification size refers to the nominal size of the main parts of metal materials (length, width, thickness, diameter, etc.).

8. Nominal size (nominal size) : it is the ideal size people want to get in production, but it has a certain gap with the actual size.

9. Dimensional deviation: The difference between the actual size and the nominal size is called dimensional deviation. Greater than the nominal size is called positive deviation, less than the nominal size is called negative deviation. Within the scope of standard regulation is called allowable deviation, exceeding the scope is called out of tolerance, and out of tolerance belongs to unqualified products.

10. Accuracy grade: the size of metal materials allows the deviation of several ranges, and according to the size of the allowable deviation is divided into a number of grades called accuracy grade, precision grade ordinary, higher, advanced, etc..

11. Delivery length (width) : refers to the main delivery size of metal materials, which refers to the length (width) specification of metal materials when they are delivered.

12. Usually length (indefinite length) : the length does not make certain provisions, but must be in a specified length range (according to different varieties, the length is not the same, according to the department, factory).

13. Short (narrow) : length less than the specified lower limit of normal length dimensions, but not less than the specified minimum allowable length. For some metal materials, a part of the “short ruler” can be handed in according to the provisions.

14. Fixed length: the length of the metal material delivered must have the length specified by the buyer in the order contract (generally positive deviation).

15. Double length: the length of the metal material to be delivered must be an integer multiple of the length specified by the buyer in the order contract (plus sawing and positive deviation).

The inspection of specifications and dimensions should pay attention to the measurement of material parts and the selection of appropriate measuring tools.

The quantity of metal materials, generally refers to the weight (except for individual cases of plate, fish tail plate by piece count), quantity inspection methods are:

17. Measured by actual weight: Generally all metal materials measured by actual weight should be weighed and inspected. For strong packing (such as cases, casks, drums, etc.), the gross weight, net weight and tare weight shall be indicated on the package. For example, the sampling quantity of thin steel plate, silicon steel sheet and ferroalloy can be no less than 5% of the batch. If the sampling weight differs greatly from the marked weight, all the samples must be unpacked and weighed.

18. According to the theory conversion measurement: to the nominal size of the material (actual size) and the weight of the specific gravity calculated, the size of the plate and other materials can be converted according to the theory, but in the conversion should pay attention to the conversion formula and the actual specific gravity of the material.

For Further Details,Please Feel Free To Contact Us: