Since different facts directly affect investment casting costs, the best way to estimate investment casting cost is to outline all factors that affect the total cost.

These different facts will have different effects on each case. A better understanding of them is essential for you to consider your castings when making your budget. Therefore, please review the following factors that may affect the investment casting total cost calculator.

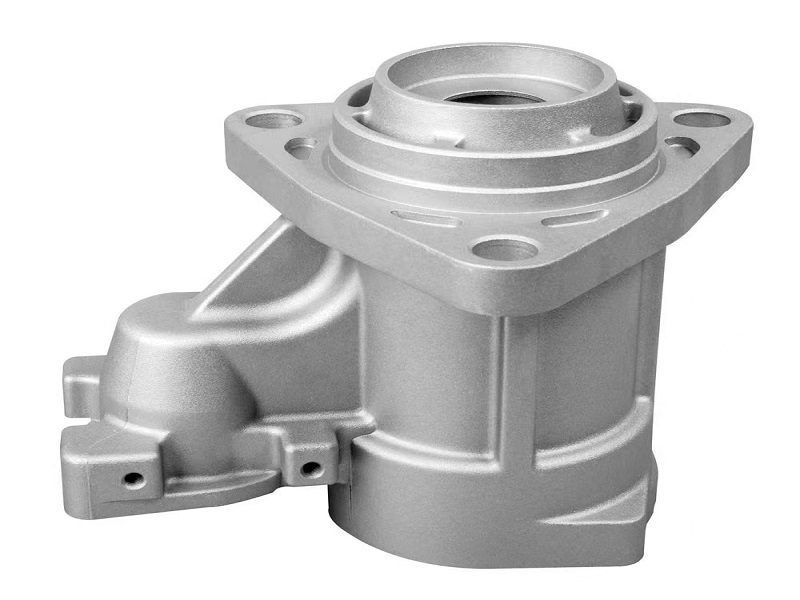

Investment casting is the most commonly used method in automobile, gun industry and railway industry. Here, we can see the unique cost of each metal due to various technologies, methods and quality requirements.

The complexity of design also affects the cost of investment casting. Complex structures may require some additional procedures and treatments. This will further increase the price of investment casting products.

The number of shell layers also affects the cost of investment casting. The more complex the design you want in your project, the more layers you will need. And investment casting costs will be more expensive.

Any investment casting company shall add labor cost estimation when calculating the total investment casting cost. The average wage of investment casting workers also has a great impact on the cost estimation of lost wax casting.

Can we reduce labor costs? Considering the calculation of the time required in the manufacturing process of investment casting mold, manual pouring of metal is essential. Also, the time required to remove the part from the mold and clean it is important. Therefore, we cannot exclude the labor cost when making the investment casting cost calculator.

When parts are manufactured in small quantities (e.g., prototypes) compared to large orders, the setup cost per part of metal investment casting is higher. With the increase of production, the cost will increase correspondingly, and the investment casting cost per metal will decrease.

For Further Details,Please Feel Free To Contact Us: