Galvanized Steel Sheet

Product Introduction of Galvanized Steel Sheet

Shandong Baowu Steel Group. Offer Galvanized Steel Sheet In Various Thicknesses, Standard Cut Lengths. Provide Custom.We will provide users with high-quality products, reasonable prices and good services.

Supply Ability:5000 Tons

Price Term:CIF CFR FOB EX-WORK

Delivery Time:within 7 days

MOQ:1 Ton

Standard:ASTMA53, ASTM A573, ASTM A283, GB/T 700-2006, GB/T711-2008, JIS G3101, JIS G3131, JIS G3016

Export Packing:Waterproof paper, and steel strip packed.

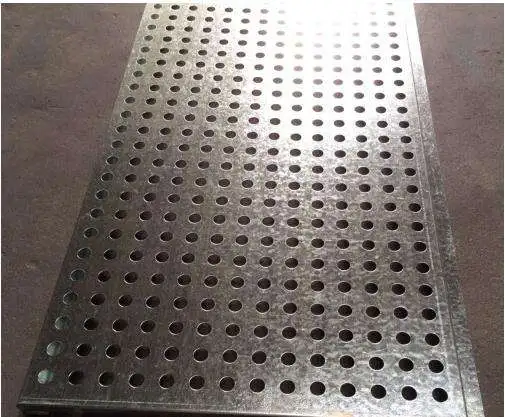

Galvanized Steel Sheet

DX51D Galvanized Steel Sheet

DX51D Galvanized Steel Sheet Our company is a professional manufacturer of galvanized steel sheet products.we believed in the best quality, reasonable price, on time delivery and

DX52D Galvanized Steel Sheet

DX52D Galvanized Steel Sheet Using advanced galvanizing process, the coating is uniform, the adhesion is strong, the service life is long, and it can be used

DX53D Galvanized Steel Sheet

DX53D Galvanized Steel Sheet Shandong Baowu using high-quality raw materials, the material is higher than the level of the same industry, complete specifications, sufficient stock, one-stop

DX54D Galvanized Steel Sheet

DX54D Galvanized Steel Sheet Raw materials through strict screening, do not cut corners, fine workmanship, quality good luster.Products are through strict screening of the company, please

S220GD Galvanized Steel Sheet

S220GD Galvanized Steel Sheet Conventional specifications are available in stock; special specifications can support customization; choose safe raw materials Supply Ability:5000 TonsPrice Term:CIF CFR FOB EX-WORKDelivery

SPCD Galvanized Steel Sheet

SPCD Galvanized Steel Sheet Galvanized steel plate is divided into ordinary electrolytic plate and fingerprint resistant electrolytic plate.Fingerprint resistant plate is added on the basis of

Galvanized Steel Sheet Available Specification

GALVANIZED STEEL COIL SHEETS GI PLATE | |

Standard | ISO,JIS,AS EN,ASTM |

Grade | Q195 Q235 Q345 |

SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 | |

SGHC SGH340 SGH400 SGH440 SGH490 SGH540 | |

DX51D DX52D DX53D DX54D DX55D DX56D DX57D | |

S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD | |

SS230 SS250 SS275 | |

Width | 600mm to 1500mm |

Thickness | 0.125mm to 3.5mm |

Zinc coating | 40g/m2 to 275g/m2 |

Coil weight | 3 tons to 6 tons |

Coil ID | 508mm or 610mm |

Surface treatment | Unoil,Dry,Chromate Passivated, Non-chromate Passivated |

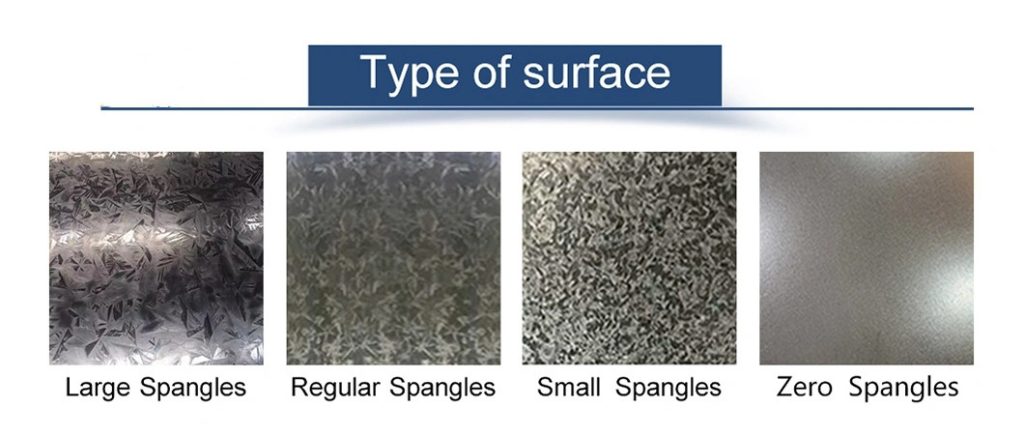

Spangle | Regular Spangle, minimum Spangle,Large Spangle, Zero Spangle |

Capacity | 1,500,000MT/year |

Delivery | 15-25 Days |

Spangle | Big Medium Small Zero |

Zinc Coating | 30-275g/m2 |

Coil Weight | 3-8 Tons |

Galvanized Steel Sheet Gauge Chart

| Galvanized Steel Sheet Gauge Chart | ||

| Gauge | mm | Inches |

| 8 | 4.27 | 0.1681 |

| 9 | 3.89 | 0.1532 |

| 10 | 3.51 | 0.1382 |

| 11 | 3.13 | 0.1233 |

| 12 | 2.75 | 0.1084 |

| 14 | 1.99 | 0.0785 |

| 16 | 1.61 | 0.0635 |

| 18 | 1.31 | 0.0516 |

| 20 | 1.01 | 0.0396 |

| 21 | 0.93 | 0.0366 |

| 22 | 0.85 | 0.0336 |

| 23 | 0.78 | 0.0306 |

| 24 | 0.7 | 0.0276 |

| 25 | 0.63 | 0.0247 |

| 26 | 0.55 | 0.0217 |

| 27 | 0.51 | 0.0202 |

| 28 | 0.47 | 0.0187 |

| 30 | 0.4 | 0.0157 |

| Gauge | mm | Inches |

| 8 | 4.27 | 0.1681 |

| 9 | 3.89 | 0.1532 |

| 10 | 3.51 | 0.1382 |

| 11 | 3.13 | 0.1233 |

| 12 | 2.75 | 0.1084 |

| 14 | 1.99 | 0.0785 |

| 16 | 1.61 | 0.0635 |

| 18 | 1.31 | 0.0516 |

| 20 | 1.01 | 0.0396 |

| 21 | 0.93 | 0.0366 |

| 22 | 0.85 | 0.0336 |

| 23 | 0.78 | 0.0306 |

| 24 | 0.7 | 0.0276 |

| 25 | 0.63 | 0.0247 |

| 26 | 0.55 | 0.0217 |

| 27 | 0.51 | 0.0202 |

| 28 | 0.47 | 0.0187 |

| 30 | 0.4 | 0.0157 |

| Standard | GB/T 2518 | EN10346 | JIS G 3141 | ASTM A663 |

| Grade | DX51D+Z | DX51D+Z | SGCC | CS Type C |

| DX52D+Z | DX52D+Z | SGCD1 | CSTypeA.B | |

| DX53D+Z | DX53D+Z | SGCD2 | FS Type A, B | |

| DX54D+Z | DX54D+Z | SGCD3 | DDS Type C | |

| S250GD+Z | S250GD+Z | SGC340 | SS255 | |

| S280GD+Z | S280GD+Z | SGC400 | SS275 | |

| S320GD+Z | S320GD+Z | – | – | |

| S350GD+Z | S350GD+Z | SGC440 | SS340 Class4 | |

| S550GD+Z | S550GD+Z | SGC590 | SS550 Class2 |

Surface Finish of galvanized steel sheets

Application of galvanized steel sheets

Construction Industry

Household appliances

Furniture industry

Transportation industry

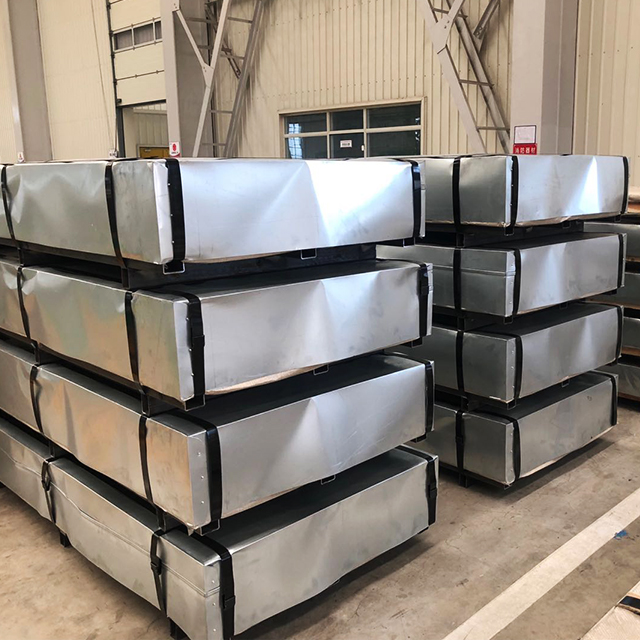

Packaging of galvanized steel sheet

Export standard package,bundled or be required.

The inner size of container is below:

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high)

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high)

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high)

Delivery Details 7-15 dyas,or according to the order quantity or upon negotiation.

FAQ

We are a factory as well as a professional manufacturer established for more than 20 years and export over 15 years.

Can provide small samples for free. Customized sample takes 5-7 days.

Small trial order takes 5-7 days. Container order need 15-20 days.

Cover with PE film , wrap with waterproof paper, pack with wooden plate,belt by steel strip, fasten on pallet.

All products we supply is primary as you need, Our company is certificated to CE, and every product will be tested for 4-5processes. We welcome customers or the third party inspection agencies to come to our factory for inspection.

Usually 30% deposit by TT in advance and balance against copy pf BL or L/C at sight.

◆The adaptability of galvanized steel sheets is generally always very popular, and the anti-corrosion period is long, but the anti-corrosion period is different in different natural environments.

◆The cost of the solution is low. The cost of antirust treatment of galvanized steel plate is lower than that of other paint coatings.

◆It is durable for a long time. Under the natural environment of suburban areas, the standardized hot-dip galvanized antirust treatment layer can last for about 50 years without repair. In urban areas or coastal areas, the standard hot-dip galvanized antirust treatment layer can be maintained for 20 years without repair.

◆Good credibility. The hot-dip galvanized layer and stainless steel plate are fused in the metallurgical industry and become a part of the rigid surface layer, so the coating resistance is relatively reliable.

◆The coating has strong ductility. The hot-dip galvanized layer produces this very metallurgical industrial structure, which can bear the damage of mechanical equipment during transportation and application.

◆Comprehensive maintenance: every part of the plated parts can be plated with zinc, and can be subject to all-round maintenance even in the concave, oblique, and hidden places.

◆Cost-saving, the whole process of hot galvanizing is more convenient than other coating engineering construction methods and can prevent the time required for brushing on the construction site after installation.

According to the production and processing method, it can be divided into the following categories.

① Hot-dip galvanized steel sheet. The steel plate is immersed in a molten zinc bath, so that its surface is attached to a layer of zinc. At present, the continuous galvanizing process is mainly used, that is, the rolled steel plate is continuously immersed in the molten zinc bath made of galvanized steel.

② Alloy galvanized steel sheet. This kind of steel plate is also made by the hot dipping method, but it is heated to about 500°C immediately after leaving the bath to form a zinc-iron alloy film. Galvanized steel sheet with good coating adhesion and weldability.

③ Electro-galvanized steel sheet. Galvanized steel sheet produced by electroplating has good workability. However, the plating is thin and the corrosion resistance is not as good as that of hot-dip galvanized sheet.

④ Single-sided galvanized and double-sided poorly galvanized steel sheets. Single-sided galvanized steel sheet, i.e., the product is galvanized on one side only. It has better adaptability than double-sided galvanized steel in terms of welding, painting, rust treatment and processing. To overcome the disadvantage of not galvanizing on one side, there is another type of galvanized steel sheet with a thin zinc layer on the other side, i.e. double-sided differential galvanized steel sheet.

⑤ Alloy, composite galvanized steel sheet. It is an alloy made of zinc and other metals such as aluminum, lead and zinc, or even a composite coated steel sheet. This steel sheet not only has excellent rust resistance, but also has good coating properties.

In addition to the above five types, there are also colored galvanized steel sheets, printed coated galvanized steel sheets, PVC laminated galvanized steel sheets, etc., but the most commonly used is still hot-dip galvanized steel sheets.

Major producing countries and importing countries.

①Main domestic production plants: Wuhan Iron and Steel, Anshan Steel, Baosteel Huangshi, Zhongyue Hengtong, Shougang, Pan Steel, Hand Steel, Ma Steel, Fujian Kaijing, etc.

②The main foreign producing countries are Japan, Germany, Russia, France, Korea, etc.

◆Try not to place it in a humid environment, because after a long time, it will inevitably cause certain damage to the galvanized sheet. After the zinc on the surface is damaged, the service life will be greatly shortened.

◆If the degree of processing is high in the process of processing, the zinc layer of the galvanized sheet may be damaged, so it needs to be confirmed before use.

◆With the passage of time, the performance of the steel plate is likely to be reduced or deformed. Therefore, in order to prevent this situation, it is best to use it as soon as possible.

◆Try not to place it in an acidic environment, which may also lead to rust of the galvanized sheet. The galvanized sheet can be placed in a dry and clean room.

(1) Tensile test:

① Performance index: Generally speaking, only structural, tensile, and deep drawing galvanized sheets have tensile performance requirements. The galvanized sheet for structure is required to have a yield point, tensile strength, and elongation, etc; Only elongation is required for stretching. See relevant product standards in “8” of this section for specific values;

② Test method: the same as the test method of general steel sheet. See the relevant standards provided in “8” and the test method standards listed in the “ordinary carbon steel sheet”.

(2) Bending test:

The bending test is the main item to measure the process performance of sheet metal, but the requirements of various national standards for various galvanized sheets are not consistent. Except for the structural level, other American standards do not require bending and tensile tests. In Japan, bending tests are required except for structural grade, building corrugated plate, and general corrugated plate.

Requirements: Generally, after the galvanized sheet is bent for 180, there shall be no separation of the zinc layer on the outer surface and no cracking and fracture on the plate base.

Common quality defects of galvanized sheet:

◆Defect Name: galvanized stripping.

Defect performance: dezincification.

Causes: poor furnace temperature, improper substrate treatment, etc.

◆Defect Name: not galvanized.

Defect performance: the surface of the steel plate is not coated with zinc.

Cause: poor raw materials. Poor degreasing and furnace temperature during pretreatment.

◆Defect Name: zinc flower defect.

Defect performance: the size of the zinc flower is uneven and there is no zinc flower.

Cause: poor temperature rise in furnace area and poor cooling control.

◆Defect Name: zinc scar.

Defect performance: spot and granular zinc slag adhesion on the surface of steel plate.

Cause: dross or low slag in the zinc pot is attached to the rigid belt.

◆Defect Name: oxidation.

Defect performance: white rust.

Cause: during storage, it absorbs moisture in the air and oxidizes.

◆Defect Name: blackspot.

Defect performance: black dot, block, and spot.

Cause of occurrence: the precipitation of impure substances reacts with water and carbon dioxide in the atmosphere, or is caused by friction during transportation.

◆Defect Name: side wave, mediumwave.

Defect performance: wavy at the edge or middle.

Cause: poor raw materials or poor working condition of straightening roller.

◆Defect Name: serrated edge.

Defect performance: the edge is in sawtooth shape.

Cause: uneven edges and serrations are formed during cold rolling of raw materials.

◆Defect Name: uneven plate surface.

Defect performance: dent.

Cause of occurrence: pits in raw materials or foreign matters on the roller surface.

Precautions for transportation and storage of galvanized sheet.

◆Store in a ventilated place to avoid dew erosion or moisture penetration.

◆Confirm that the packaging paper is not damaged during storage.

◆Shorten the storage time as much as possible and protect its performance before corrosion.

◆If the plate is subjected to abnormal external pressure, the zinc layer will fall off partially.

◆Prevent dirt and oil powder from adhering to the surface, which will affect the galvanizing effect.

◆Skid or support frame shall be added under the steel plate, and rain cloth shall be covered during transportation.

(1)Galvanized steel sheet will rust. Depending on the environment where the galvanized steel sheet is located, the reaction will be different. If the galvanized steel sheet is placed outdoors for a long time, the galvanized steel sheet will also rust. Du galvanized sheet is placed indoors and kept dry. Do not let the galvanized sheet get water stains and corrosive liquids, so the rust time of the galvanized sheet will be prolonged.

(2)It is a normal phenomenon that galvanized steel sheet is corroded and rusted because galvanized steel sheet contains other impurities, such as iron and zinc, and other metals, which will easily produce corrosion effects and cause rusting of galvanized sheet.

(3)Although galvanized steel sheet has certain corrosion resistance and rust resistance, the capacity of galvanized steel sheet is also limited. If it is placed in a harsh environment for a long time, all-steel sheets will rust.

Galvanized steel sheets are also divided into cold-dip galvanized steel sheets and hot-dip galvanized steel sheets. Generally, cold-dip galvanized steel sheets are easier to rust, while hot-dip galvanized steel sheets are not easy to rust.

(1) Improve the surface flatness of the galvanized sheet. After smoothing, the flatness of the galvanized sheet is improved to a certain extent, and the wave shape of the galvanized sheet is partially eliminated. At the same time, the slag particles or other uneven spots on the surface can be flattened to make the surface smooth.

(2) Adjust the surface roughness of the galvanized sheet. By controlling the surface roughness of the work roll of the finishing machine, the original uneven roughness of the galvanized sheet surface can be unified to a certain range. This can improve the paintability of the product and the lubricity during processing.

(3) Improve the surface color of the galvanized sheet. For small spangles and spangle-free products, smoothing can make the galvanized sheet get a more uniform gloss surface. For some private enterprises using large spangle products as color-coated substrates, the spangle bumps and different glosses formed by the crystallization of the large spangles can be smoothed and unified, making the spangles blurred, which is beneficial Cover the spangles during painting.

Improve the processing performance of galvanized sheets. Through smoothing, the yield platform of the galvanized sheet can be disappeared or be inconspicuous, which can prevent the occurrence of metal slip lines in the subsequent processing.

(1)For painting galvanized iron plates, special paint must be used. ED1000 epoxy primer is an anticorrosive paint dedicated to galvanized substrates. It has very good adhesion to ensure that the paint film does not fall off and has excellent corrosion resistance.

(2) Use dry sanding paper to evenly polish the surface of the car body to feathery edges. Note: The anti-corrosion material on the surface of the galvanized sheet must not be penetrated, so as not to affect the anti-corrosion performance of the material itself.

(3) Use a dust blower to blow away dust particles on the surface.

(4)Spray or brush the phosphate primer, and spray the top coat after the phosphate primer is dry.

(5) Galvanized iron sheet is different from ordinary iron sheet. After galvanizing, the surface properties have changed. The surface of the zinc layer is smooth, most of the paint can not adhere to it, it is very easy to peel off the paint, and it can not play the role of anti-corrosion protection. . Although galvanizing has a certain anti-corrosion effect, it is still necessary to use paint for application in harsh environments.

(1) Due to the presence of a zinc layer with low resistivity, low hardness, and low melting point on the contact surface, the contact resistance is reduced and the current field is unevenly distributed, which affects the formation and size of the nugget;

(2) Under the guarantee of satisfactory welding quality, the applicable welding parameter range is small; due to the low melting point of the zinc layer, the surface is easy to burn, and it easily reacts with the electrode cap to form brass, which will affect the conductivity of the electrode and cause the output current Too small, easy to overheat and deform, reduce electrode life and affect welding quality.

(3) As the zinc layer is not conductive during welding of galvanized sheet, welding spatter is prone to occur during welding, which affects the stability of solder joint quality;

(4)During the spot welding process of galvanized steel sheet, due to unreasonable welding specifications, some zinc will remain in the joint. The zinc-iron alloy may form small cracks or pores during the nugget crystallization process, and a softened structure will be formed when there is more residual zinc. , Affect the quality of solder joints.

In the past, zinc ingots used for galvanizing contained more or less a certain amount of lead, mainly because zinc and lead always existed together in the process of smelting, distillation, and condensation of zinc ore. Therefore, people can always see the zinc flower pattern on the surface of galvanized products. In recent years, the purity of zinc produced by the electrolytic recovery method can reach more than 99.99%, so that there is no lead in zinc. Since then, zinc plating manufacturers can produce zinc-free products by using lead-free (about ≤ 0.01%) or low lead (about 0.01% – 0.05%).

The lead-free or low-lead process is to reduce the lead content in the zinc solution, so that the zinc layer increases the number of nucleation points during the solidification process, resulting in an increase in the nucleation speed and at the same time reducing the grain growth speed, thereby preventing the spangle grains Grow up. Spangle-free products do not have a large amount of grain boundary thinning and spangle undulations, and a very smooth surface can be obtained after smoothing. After this product is painted, high-quality painted products can be obtained. At the same time, another benefit of lead-free spangles is that they will not produce intergranular corrosion. Intergranular corrosion is caused by the concentration of lead at the grain boundary, which causes the mechanical properties of the zinc layer to decrease under the influence of the humid environment.

The galvanized sheet for construction has a service life of 19 years and is mainly used for the sealing and rust prevention of metal product components and materials such as galvanized sheets. Scope of application: It is suitable for the sealing and antirust treatment of galvanized sheets, metal product components, and materials. The upper flux immerses the steel components in the mixture of zinc chloride and ammonium chloride so that the surface of the components is separated from the air.

The service life of galvanized tinplate in the open-air depends on two factors. First, the use of environmental conditions, the concentration of salt fog, acid fog, inland, and coastal areas are different; second, the thickness of the zinc layer of tinplate. Generally, the annual consumption of the galvanized layer is between 1-1.5 microns/a under natural inland environmental conditions.

Generally speaking, there will be a life span of more than 10 years, because the spray paint contains acidic components, and when it reacts with zinc and iron, hydrogen gas is easily generated, so the paint is prone to bubbling and then falling off. Therefore, before applying paint, a layer of phosphating primer should be applied first, and then the topcoat should be applied.

Galvanized sheet refers to a steel sheet coated with a layer of zinc on the surface. Galvanizing is an economical and effective anti-corrosion method that is often used. About half of the world’s zinc production is used in this process. Galvanized steel sheet is to prevent corrosion on the surface of the steel sheet and prolong its service life. The surface of the steel sheet is coated with a layer of metal zinc. This kind of galvanized steel sheet is called galvanized sheet.

1. The concept is different; galvanizing refers to coating a layer of metal zinc on the surface of the steel plate, the purpose is to prevent the surface of the steel plate from being corroded, and to extend its service life. This kind of zinc-coated thin steel plate is called a galvanized sheet. Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, and water, and chemically corrosive media such as acids, alkalis, and salts. It is also called stainless acid-resistant steel.

2. The processing technology is different; galvanizing is mainly to plate a dense layer of zinc on the surface of the steel. Stainless steel is the addition of other metal elements inside the steel, and the internal structure changes to prevent the product from rusting.

3. Different fields of application; galvanized steel strip products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery, and commerce industries. Such as building roof panels, roof grilles, etc.; kitchen utensils, etc.; materials storage and transportation, packaging utensils, etc. Stainless steel is mainly used in the construction field. It is one of the strongest metal materials used in construction. It is also used in food processing, catering, brewing, and chemical industries that require high sanitary conditions.

1. Look at the surface of galvanized sheet

Zinc is a metal that is generally silver-white and has a high status in modern industry and is often used by people. The batteries that people often see around basically rely on it to complete. Coating a layer of zinc on the steel plate is a galvanized sheet. The surface of this galvanized sheet is indistinguishable from ordinary steel sheets, but it feels smooth and flat to the touch, without any unevenness.

2. look at the material of galvanized sheet

There are many kinds of steel plates on the market, one of which is similar to galvanized steel, that is, galvanized steel. So, is the galvanized sheet the same as the galvanized steel sheet? Of course, it is not the same. The material of galvanized steel sheets is mainly steel. The hardness of steel is very high. The hardness of an ordinary sheet is not as good as that of steel. Although the surface of the sheet is galvanized, it is still different. When purchasing steel, users must choose a good hardness, so that the use time can belong.

3. Start with durability

Generally speaking, the steel on the market has the same thickness specifications. The thickness specification of galvanized steel sheet should be selected according to the user’s construction situation, do not choose blindly. Plating a layer of zinc on the steel plate is equivalent to having a protective film. This protective film has the ability to prevent corrosion, which means that it has a considerable advantage in durability and can be used for a longer time.

Surface condition: The surface condition of galvanized steel varies depending on the treatment method during the coating process, such as ordinary zinc bloom, fine zinc bloom, flat zinc bloom, zinc bloom without zinc, phosphated surface, etc. The German standard also specifies the surface grade.

(2) Galvanized sheet shall have a good appearance and shall not have defects such as no coating, holes, cracks and scum, excessive coating thickness, scratches, chromic acid stains, white rust, etc. that are detrimental to the use of the product. . Foreign standards are not very clear about the specific appearance defects. Some specific defects should be listed in the contract when ordering.

In recent years, China’s galvanized steel production has increased year by year, and imports have also increased year by year, even higher than the increase in production; minus production duplication statistics, galvanized steel consumption is about 5.27 million tons. After 1999, galvanized sheet imports exceeded production for the first time, and the self-sufficiency rate of domestic products was less than 50%, with a declining trend year by year.

(1) Galvanized sheet consumption status

In recent years, the increase in domestic galvanized sheet production is mainly due to the increase in hot-dip galvanized sheet production. From 1998 to 2002, the production of hot-dip galvanized sheet increased from 970,000 tons to 2.2 million tons; while the import volume grew faster. It increased from 370,000 tons in 1998 to 1.56 million tons in 2002; apparent consumption increased from 1.32 million tons to 3.67 million tons. The domestic product self-sufficiency rate of hot-dip galvanized sheet was about 60% in 2002. Domestic production and imports of hot-dip galvanized sheet increased from the previous year. The increased demand for thin gauge hot-dip galvanized sheets for the production of color-coated sheets has led to a decrease in the domestic product self-sufficiency rate.

(2) Current consumption status of electro-galvanized sheet

In recent years, with the rapid development of the domestic automobile market, the basic popularity of household appliances and personal computers, the massive export of electronic products, and the development of the security door market, there has been an increasing demand for electro galvanized sheet. It is growing too fast. At present, the scale of production of electric galvanized sheet in China, whether in terms of quantity, variety or quality, cannot meet the needs of the domestic market. From 1998 to 2002, domestic production of electro-galvanized sheet grew slowly, from 170,000 tons to 400,000 tons; while imports grew rapidly, from 730,000 tons to 1.78 million tons; and apparent consumption increased from 870,000 tons to 2.16 million tons. The self-sufficiency rate of domestic products is less than 20%.

Hot-dip galvanized sheet is a hot-rolled galvanized sheet, and a cold-dip galvanized sheet is a cold-rolled galvanized sheet. In terms of materials, the composition of the two types of galvanized sheets is basically similar. The difference is that cold-dip galvanized sheets are better than hot-dip galvanized sheets. The steel is thinner, the surface quality is better, and the process is more complicated. The price is higher. From the process point of view, the steel is sent from the cast billet to hot rolling and rolled into a certain thickness of plate, such as a thickness of about 10mm, if If the user does not have higher requirements for the surface, thickness, and mechanical strength of the plate, the finished product can be processed, such as galvanizing, etc., and sold directly, which is a hot plate. If the plate has higher requirements, then the hot rolled plate is sent to the cold rolling line for reprocessing. After pickling, annealing, and rolling again, a thinner, smoother surface and better mechanical properties are obtained.

| Specification | Zinc Layer | Material |

| 0.20*1000*C | 80 | DX51D+Z |

| 0.25*1000*C | 80 | DX51D+Z |

| 0.3*1000*C | 80 | DX51D+Z |

| 0.35*1000*C | 80 | DX51D+Z |

| 0.4*1000*C | 80 | DX51D+Z |

| 0.5*1000*C | 80 | S280GD+Z |

| 0.5*1000*C | 80 | DX51D+Z |

| 0.58*1000*C | 80 | S350GD+Z |

| 0.6*1000*C | 80 | DX51D+Z |

| 0.7*1000*C | 80 | DX51D+Z |

| 0.75*1000*C | 80 | DX51D+Z |

| 0.8*1000*C | 80 | DX51D+Z |

| 0.8*1000*C | 80 | DX53D+Z |

| 0.85*1000*C | 80 | DX51D+Z |

| 0.9*1000*C | 80 | DX51D+Z |

| 0.98*1000*C | 80 | DX51D+Z |

| 0.95*1000*C | 80 | DX51D+Z |

| 1.0*1000*C | 80 | DX51D+Z |

| 1.1*1000*C | 80 | DX51D+Z |

| 1.2*1000*C | 80 | DX51D+Z |

| 1.2*1050*C | 150 | CSB |

| 1.4*1000*C | 80 | DX51D+Z |

| Specification | Zinc Layer | Material |

| 1.5*1000*C | 80 | DX51D+Z |

| 1.55*1000*C | 180 | S280GD+Z |

| 1.55*1000*C | 180 | S350GD+Z |

| 1.6*1000*C | 80 | DX51D+Z |

| 1.8*1000*C | 80 | DX51D+Z |

| 1.9*1000*C | 80 | DX51D+Z |

| 1.95*1000*C | 180 | S350GD |

| 1.98*1000*C | 80 | DX51D+Z |

| 1.95*1000*C | 180 | S320GD+Z |

| 1.95*1000*C | 180 | S280GD+Z |

| 1.95*1000*C | 275 | S350GD+Z |

| 2.0*1000*C | 80 | DX51D+Z |

| Specification | Zinc Layer | Material |

| 0.36*1250*C | 80 | |

| 0.4*1250*C | 80 | DX51D+Z |

| 0.42*1250*C | 80 | DX51D+Z |

| 0.45*1250*C | 225 | S280GD+Z |

| 0.47*1250*C | 225 | S280GD+Z |

| 0.5*1250*C | 80 | SGCC |

| 0.55*1250*C | 180 | S280GD+Z |

| 0.55*1250*C | 225 | S280GD+Z |

| 0.6*1250*C | 80 | DX51D+Z |

| 0.65*1250*C | 180 | DX51D+Z |

| 0.7*1250*C | 80 | DX51D+Z |

| 0.7*1250*C | 80 | SGCC |

| 0.75*1250*C | 80 | DX51D+Z |

| 0.8*1250*C | 80 | DX51D+Z |

| 0.9*1250*C | 80 | DX51D+Z |

| 0.95*1250*C | 80 | DX51D+Z |

| Specification | Zinc Layer | Material |

| 1.0*1250*C | 80 | DX51D+Z |

| 1.15*1250*C | 80 | DX51D+Z |

| 1.1*1250*C | 80 | DX51D+Z |

| 1.2*1250*C | 80 | DX51D+Z |

| 1.35*1250*C | 80 | DX51D+Z |

| 1.4*1250*C | 80 | DX51D+Z |

| 1.5*1250*C | 80 | DX51D+Z |

| 1.55*1250*C | 80 | DX51D+Z |

| 1.6*1250*C | 120 | SGCC |

| 1.6*1250*C | 80 | DX51D+Z |

| 1.8*1250*C | 80 | DX51D+Z |

| 1.85*1250*C | 90 | DX51D+Z |

| 1.95*1250*C | 80 | DX51D+Z |

| 1.75*1250*C | 80 | DX51D+Z |

| 2.0*1250*C | 80 | DX51D+Z |

| 2.0*1250*C | 120 | SGCC |

| 2.5*1250*C | 80 | DX51D+Z |

1. Zinc-free galvanized sheet

Adding spangle accelerating elements in the zinc liquid, no spangles are formed when the zinc layer is solidified, and the crystal grains are very fine, smooth, and smooth, so it is called a spangle-free product. It has superior corrosion resistance and good coating performance.

2. Large spangle galvanized sheet

Spangle accelerating elements are added to the zinc solution, so beautiful spangles are formed when the coating is solidified. In the initial stage of use, the appearance performance is good, but the crystal grains are coarse and there is fine unevenness.

3. small spangle galvanized sheet

There is no strict definition of small spangle products. Generally, products with smaller spangles are called small spangle products. Small spangle products are made of the same ingredients as large spangle products. In order to overcome the poor coating performance of large spangle products, various methods are used to inhibit the growth of spangles during cooling, and it is best to form a small diameter. Spangle. Because it does not have a mirror-like smooth surface like large spangles, and it is not as smooth as a spangle-free product, the coating performance is very good.

4. smooth spangle galvanized sheet

Smoothing spangles are galvanized products on the basis of no spangles or small spangles, and the surface is smoothed again to make the surface smoother and more suitable for the needs of modern industrial products.

The metal activity of zinc is stronger than that of iron. When two metals are in contact, the electrons of zinc will flow to iron. That is to say, when the iron is oxidized, zinc is consumed, thereby protecting the iron. This is in the dam gate of the reservoir and the ship. The above is very common. Another argument is that the metal of zinc is relatively mobile and is easily oxidized in the air, forming a dense oxide film, which protects the metal.

Hot Products

Share to: