Gratings are designed to reduce the risk of slips and falls and can be installed anywhere where these accidents are at high risk. It can be used in any indoor or outdoor location and is ideal for areas where there is an increased risk of slips and falls due to water, mud, ice, snow, grease or other cleaners. The nature of the grille design allows for the discharge of fluid, mud or dirt and ensures that the sidewalk is not slippery.

Gratings are manufactured at fixed lengths, allowing one person to complete the installation, and the modular nature of the gratings means maximum adaptation to a variety of environments, regardless of the required length.

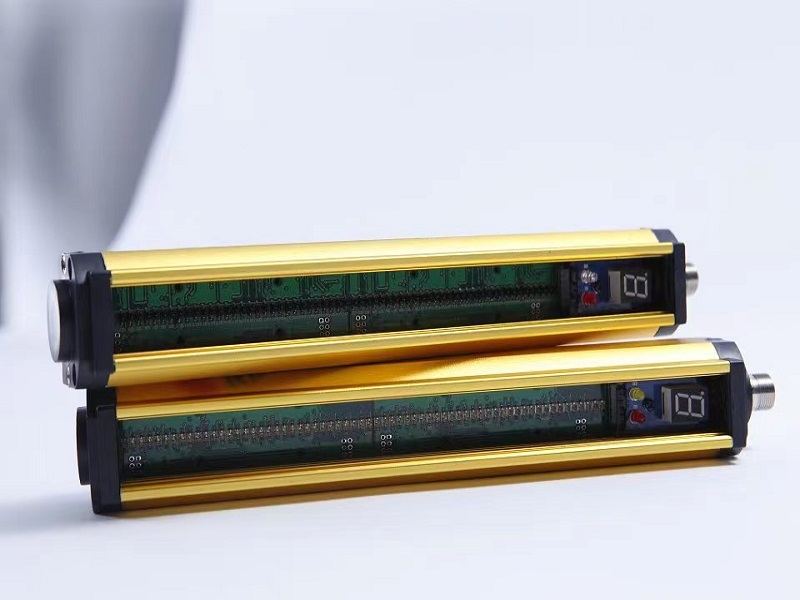

The luminescent device emits several invisible infrared beams, and the receiver receives the infrared beams from the luminescent device, forming a rectangular detection curtain. The whole grating is detected by beam-by-beam scanning. Any opaque object larger than a certain size (such as a part of the operator’s body, opaque workpiece, etc.) invading the light curtain area, will cause shading. When the safety grating detects the blackout, it will enter the “abnormal” state – interrupt output (such as relay from closed to open state, transistor into cutoff state, etc.) within 20ms of response time.

For Further Details,Please Feel Free To Contact Us: