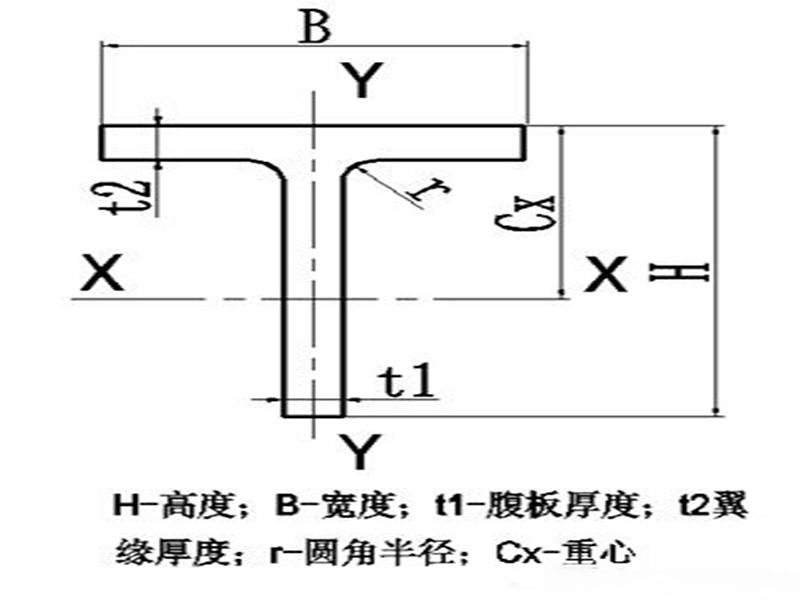

1, web width: 200-700mm

2, web thickness: 9-16mm

3, panel width: 90-300mm

4, panel thickness: 14-38mm

5, workpiece length: 5000-20000 mm

6, welding speed: 200-1500mm /min

7. Program control: PLC

8, welding power supply: imported or domestic welding machine

9. Welding form: transverse fillet welding

10, positioning clamp: hydraulic device, screw screw device

11. Maximum pressure of hydraulic system: 6.3mpa

12, the speed of the input roller table: 500-4200mm /min (controlled by ac inverter)

13. Output roller table speed: 500-4200mm /min (controlled by AC inverter)

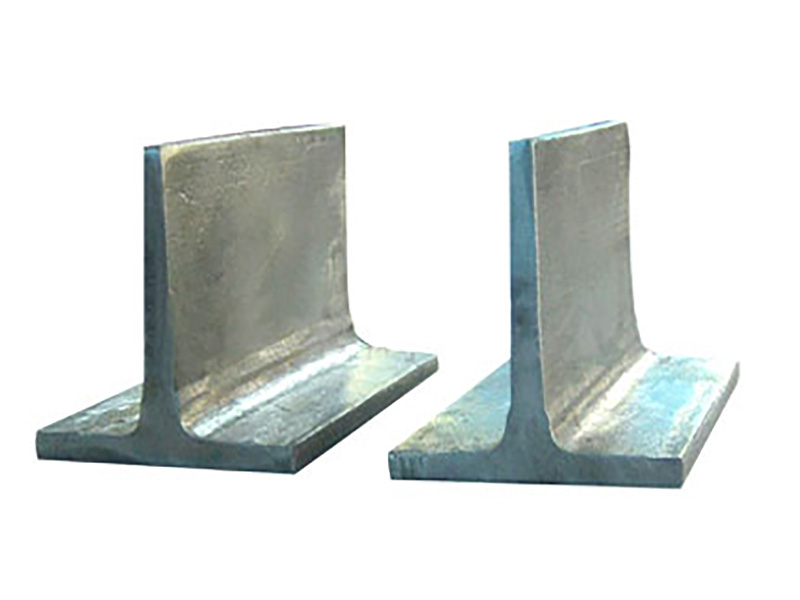

T section steel;The equipment is mainly composed of input roller table, output roller table, main engine, discharging device, electrical control system, hydraulic system and welding system.

1 HHX700 T section steel automatic welding production line:

1.1 Increased the function of setting and orthopedic, improve the utilization rate of equipment, reduce investment. (Multi-purpose of one machine)

1.2 Compact overall structure, reasonable configuration, convenient operation, fewer personnel. (The whole production line only needs two people, one person to operate, one person to lift the workpiece);

1.3 The production line integrates mechanical, electrical, hydraulic and other manufacturing, control high-tech as one, accurate movement, reliable performance. (high efficiency, high speed, high quality);

Input setting mechanism;

2.1 Automatic Panel alignment. (To ensure the positioning accuracy of the workpiece);

2.2 Web flipping, vertical, centralizing and panel automatic alignment. (reduce operation time and improve productivity);

2.3 The speed of the input and output raceway can be coordinated with the host by frequency conversion (flexible and diverse);

Host:

3.1 The panel and web precise positioning device is composed of two groups of precise positioning mechanisms (to improve positioning accuracy, ensure weld accuracy and overcome tail wagging phenomenon);

3.2 Positioning clamping mechanism is composed of mechanical screw and hydraulic cylinder (fast, accurate and high precision);

3.3 The performance of hydraulic movable beam is reliable and the pressure is adjustable (ensure the assembly gap between panel and web, and provide strong propulsion force for panel correction);

3.4 The weld accuracy is guaranteed by the gun feeding mechanism and precise positioning device (the weld track follows the welding gun to solve the influence of welding slag splashing on the tracking mechanism). ;

3.5 The gun feeding mechanism is flexible and reliable, and the position and Angle of the welding gun can be adjusted in multiple directions; (To ensure the smooth implementation of double gun double wire single molten pool high-speed welding process)

3.6 High speed welding process with double guns and double wires, welding speed up to 1500mm/min, improve production efficiency (high speed and efficiency)

4 Panel orthopedic mechanism:

4.1 The orthopedic roller adopts eccentric wheel device (through eccentric adjustment, to adapt to the smooth orthopedic T section steel of different thickness panel);

4.2 Use of welding waste heat for panel correction (labor-saving, easy to correct).

For Further Details,Please Feel Free To Contact Us: