At present, many kitchen factories, door factories, elevator factories, furniture factories and decoration companies use stainless steel plates in large quantities. Then, most of the surfaces are treated. This is a brief introduction to the surface treatment of some decorative stainless steel sheets (cold-rolled stainless steel sheets).

When stainless steel comes out of a large steel plant, it is a complete roll with a fog-like surface, commonly known as 2B surface; there is also a surface called BA (referring to stainless steel surface 2B and BA respectively), and the brightness of this surface is generally called 6K. Therefore, we see various colors, patterns and shapes of stainless steel plate to be processed in the future.

1. Brushed (frosted):

Usually, after the surface of stainless steel is processed by mechanical friction, the surface state is a straight line (also called frosted), including wire drawing, and grain, and corrugation.

Processing quality standard: the texture is uniform in thickness and depth, and the texture on each side of the product is natural and beautiful according to the design and construction requirements. The bending position of the product is allowed to have a slight messy texture that does not affect the appearance.

2. Mirror surface:

A bright surface effect obtained by using high-quality oilstone, diamond abrasive paste and different grades of sandpaper through rough grinding, medium grinding and fine grinding by polishing and grinding equipment.

Processing quality standard:

No sand and hemp texture (orange peel).

The surface should be flat, and there should be no concave protrusions or undulating wavy surfaces (distorting mirrors).

There are no residues, sand holes, scars, impurity spots, bruises, scratches on the blank surface.

The brightness reaches 8K, and the brightness of the finely ground mirror exceeds 8K.

Glossary definition: “8” in 8K refers to the ratio of alloy composition, “K” refers to the level of reflectivity after polishing (K level is the mirror reflection level), 8K mirror is chrome-nickel alloy The specular grade embodied by the steel.

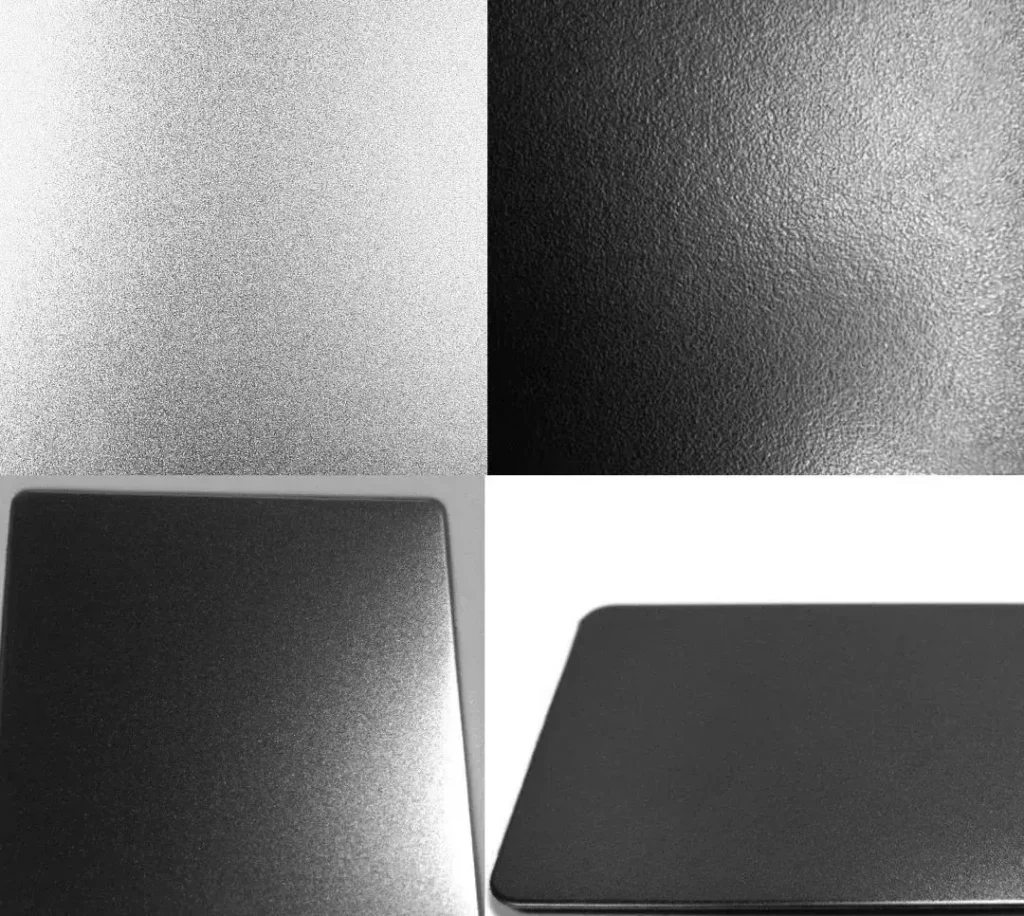

3. Sand blasting (shot):

Compressed air is used as the power to form a high-speed jet beam to spray the spray material (quartz sand, corundum) onto the surface of the workpiece to be treated at high speed, so that the surface of the board presents a fine bead-like sand surface, forming a unique decorative effect.

4. Etching:

The process principle of chemically etching patterns and texts on the surface of stainless steel is to cover the part of the surface that will not be etched with a special corrosion-resistant layer, shield the acid, so that the acid can only contact the surface of the part to be etched, and achieve the etching pattern from the surface. The purpose of the text.

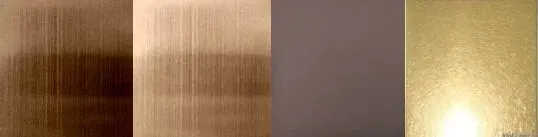

5. Titanium plating:

Also called stainless steel titanium/zirconium coating, it is to form an ion film layer of titanium/zirconium compound on the surface of stainless steel in a vacuum container, and the film layer can not fade for many years in the outdoor environment.

Titanium plating principle: In high temperature, vacuum titanium gold furnace, titanium and zirconium metals are ionized by the glow discharge of inert gas to ionize metal or alloy vapor, and the ions are accelerated by an electric field to deposit on a negatively charged stainless steel plate, thereby forming a color Rich and colorful metallic film.

6. Anti-fingerprint:

Stainless steel anti-fingerprint plate is a kind of composite coating plate obtained after anti-fingerprint treatment on the surface of stainless steel. The coating method is mainly roller coating.

The process of anti-fingerprint treatment is originally to meet the needs of users in the field of home appliances. During the production process, due to the needs of the process, many parts are manually touched many times, and sweat stains are easy to form pollution on the surface of the parts, which affects the appearance. The research and development of anti-fingerprint board That’s how it starts.

For Further Details,Please Feel Free To Contact Us: