Wire drawing can be made into straight lines, random lines, threads, ripples and spiral lines according to the needs of decoration.

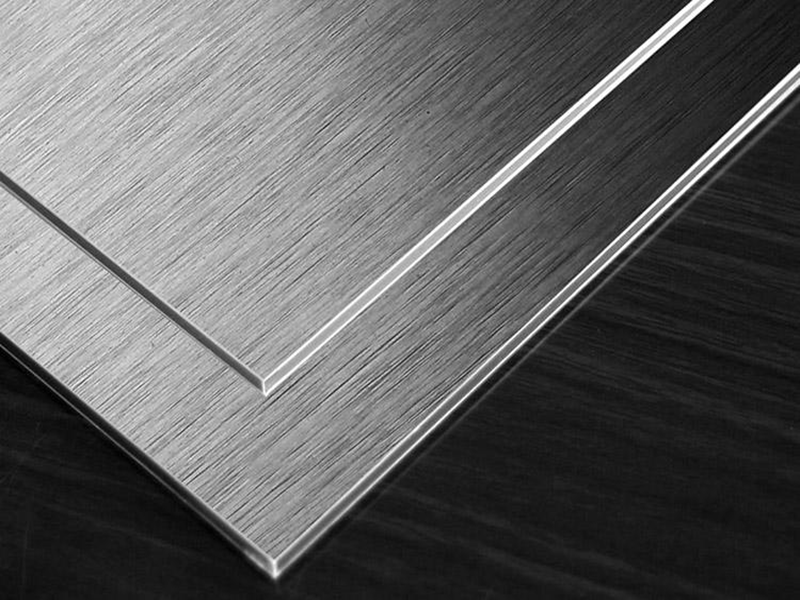

Straight line wire drawing refers to machining straight lines on the surface of aluminum plate by mechanical friction. The utility model has the dual functions of removing scratches on the surface of aluminum plate and decorating the surface of aluminum plate. There are two kinds of straight line drawing: continuous line drawing and intermittent line drawing. Continuous silk lines can be obtained by continuous horizontal and linear friction on the surface of aluminum plate with cleaning cloth or stainless steel brush (such as manual technical grinding under the condition of * existing device or grinding and brushing on aluminum plate with steel wire brush clamped by planer). Changing the steel wire diameter of the stainless steel brush can obtain lines of different thickness. Intermittent silk lines are generally processed on a polishing machine or a texturing machine. Preparation principle: two groups of differential wheels rotating in the same direction are adopted. The upper group is a fast rotating grinding roller and the lower group is a slow rotating rubber roller. Aluminum or aluminum alloy plate passes through the two groups of rollers and is brushed with fine intermittent straight lines.

Random wire drawing is a kind of irregular matte wire pattern without obvious lines obtained by moving and rubbing the aluminum plate back and forth under the high-speed copper wire brush. This kind of processing has high requirements for the surface of aluminum or aluminum alloy plate.

Corrugations are generally made on a polishing machine or a texturing machine. Using the axial movement of the upper set of grinding rollers, grind and brush on the surface of aluminum or aluminum alloy plate to obtain wavy lines.

Rotary pattern, also known as optical rotation, is a kind of silk pattern obtained by rotating and polishing the surface of aluminum or aluminum alloy plate with cylindrical felt or stone grinding nylon wheel installed on the drilling machine and kerosene mixed with polishing ointment. It is mostly used for decorative processing of circular signs and small decorative dial.

Thread is a small motor with round felt on the shaft, which is fixed on the table at an angle of about 60 degrees with the edge of the table. In addition, a carriage with fixed aluminum plate for tea pressing is made, and a polyester film with straight edge is pasted on the carriage to limit the thread competition. The rotation of the felt and the linear movement of the carriage are used to spin and wipe the thread pattern with the same width on the surface of the aluminum plate.

The specific content of the wire drawing process. The surface wire drawing of plastic parts is generally done by bronzing. Under the action of high temperature and high pressure of the bronzing machine, the material on the bronzing film is transferred to the plastic surface. Using different bronzing films, you can get different gloss and thickness of grain effects. This process is widely used on the panel of DVD player. At present, many magic mirror ornaments are used in audio-visual products, that is, the reflective film (also electroplated) aluminum surface treatment stamped on PMMA plate. In addition to wire drawing, sand blasting process is also commonly used, which can also cover scratches and beautify the appearance. In addition, there is a “bronzing” process (electrochemical aluminum transfer), Similar effects can be made on the surface of plastic parts.

1. Red copper is the best material for the hot stamping plate, that is, the pressure head, because red copper has good heat dissipation and heat transfer. It is a neutral material in the metal, which is neither too soft nor too hard. It is not only convenient for processing, but also has certain elasticity and good durability; However, in actual use, in order to reduce the material cost, many manufacturers choose aluminum alloy printing plate, which can save some in the production cost of hot plate. However, because the aluminum material is too soft and its service life is poor, if the batch is large, it will have to make plate again for a period of time, and the plate making fee is not cheap, so we should comprehensively consider the material selection.

2. It is easy to understand the hot stamping process conditions, that is, hot stamping pressure, hot stamping temperature and hot stamping time.

3. The most important thing is the choice of bronzing raw materials, that is, bronzing paper. When choosing, we should pay attention to matching with different hot stamping substrates. Not one kind of bronzing paper can eat all materials, which is mainly related to the adhesion firmness during heat transfer. This may be inconvenient to compare directly, because the two processes are suitable for different occasions. Wire drawing is suitable for sheet metal parts, while bronzing is suitable for paper, plastic and fabric. If you want to compare, you have to consider other cost changes caused by different mold and structural design.

If you simply make a simple comparison, such as the cost of wire drawing and bronzing of Sony panel above, wire drawing will be slightly cheaper. But I think other cost differences caused by material changes far exceed this cost.

In the occasion of emphasizing appearance, there are also wire drawing after electroplating. However, the electroplating layer should be thick and the wire drawing depth should be controlled reasonably. Of course, the cost has increased.

At present, the surface of general aluminum alloy products is not electroplated, but various colors produced by oxidation.

I have heard of anodizing. For aluminum, it is mainly to strengthen the surface hardness (a layer of ceramics) and enhance the anti friction performance.

Ask, can we do surface wire drawing for die-casting aluminum parts? I just have this demand here, help!!

Anodizing and strengthening its surface hardness (a layer of ceramics) to enhance its friction resistance is not a thing

Bronzing also belongs to a kind of heat transfer printing.

In this post, I have replied to some brief introductions about water transfer printing. Please refer to:

Die casting aluminum parts can be subject to surface wire drawing treatment, and then sprayed with a protective film after wire drawing treatment. It should be a layer of paint to prevent oxidation.

Can the surface of die-casting aluminum parts be oxidized to achieve a surface sanding and matte effect!

Of course, die castings can also be subject to surface oxidation treatment, and the surface matte can be achieved, but the sanding effect should be realized through the sand blasting process, which is the preliminary process of surface oxidation treatment. The sand blasting process is briefly introduced as follows:

Sand blasting is to obtain the surface of film light decoration or fine reflection surface, so as to meet the special design needs such as soft luster. At the same time, it can make the combination of printing material and substrate more firm during silk screen printing. Sand blasting is usually carried out in a special sand blasting machine. According to the requirements of sand surface thickness, quartz sand with appropriate mesh shall be selected and sprayed into appropriate sand surface. Uniform and moderate sand blasting can basically overcome the common defects on the surface of aluminum.

In fact, plastic can be directly electroplated with wire drawing lines, which is almost the same as that of aluminum

At present, the surface of general aluminum alloy products is not electroplated, but various colors produced by oxidation.

The surface of wrong aluminum alloy products is electroplated, and the surface of aluminum alloy products cannot be oxidized. Only pure aluminum products can be oxidized.

For Further Details,Please Feel Free To Contact Us: