Although most grades of aluminium have adequate appearance and corrosion resistance in many cases, these properties sometimes need to be further improved. This can be achieved by a process called anodizing. Anodic oxidation is a metal coating process, which can increase the alumina content on the surface of aluminium substrate, thus potentially improve its corrosion resistance and change its appearance. Although many different aluminium alloys and grades can be anodized, some aluminium alloys are better suited to the process than others.

The series covers pure aluminium. The aluminium in this series can be anodized. The resulting alumina layer is transparent and somewhat shiny. Because the bottom layer of pure aluminium is relatively soft, these anodized aluminium alloys are easily damaged and lack mechanical properties compared to other series of it.

This series is used to represent the alloying of aluminium and copper. The copper in these alloys forms a very strong and hard aluminium alloy. Although copper can be used to improve the mechanical properties of aluminium, unfortunately it makes these alloys poor candidates for anodizing. After anodizing, 2XXX aluminium alloy has a yellow oxide layer, which is not usually considered attractive. In addition, the anodic oxidation layer provides poor protection to the underlying aluminium alloy.

Aluminium alloys containing manganese belong to this series. Although the anodic oxide layer provides good protection for the manganese alloy aluminium substrate, it will produce an undesirable brown color. In addition, the brown color may vary from substrate to substrate, especially depending on the grade. This makes it difficult to maintain similar colors in the 3XXX series of aluminium components.

4XXX series consists of aluminium alloy and silicon. The anodized 4XXX material is well protected by the alumina layer produced by the anodic oxidation process. However, it should be noted that the 4XXX series is dark gray, lack of aesthetic. 4XXX aluminium alloys are commonly used for welding other alloys such as 6XXX, but if these welding components are anodized, the weld metal will not match the color of the base metal.

The series represents aluminium alloyed with manganese. After anodizing, the 5XXX series alloys form a strong and transparent oxide layer. They are excellent candidates for anodic oxidation; however, there are some important considerations when anodizing 5XXX series alloys. For example, some alloy elements, such as manganese and silicon, need to be kept within a certain range; in addition, the anodizing process used is also important. These alloys can usually be replaced with 4XXX series alloys for welding filler metals so that the weld color does not differ from the rest of the anodic aluminium oxide assembly

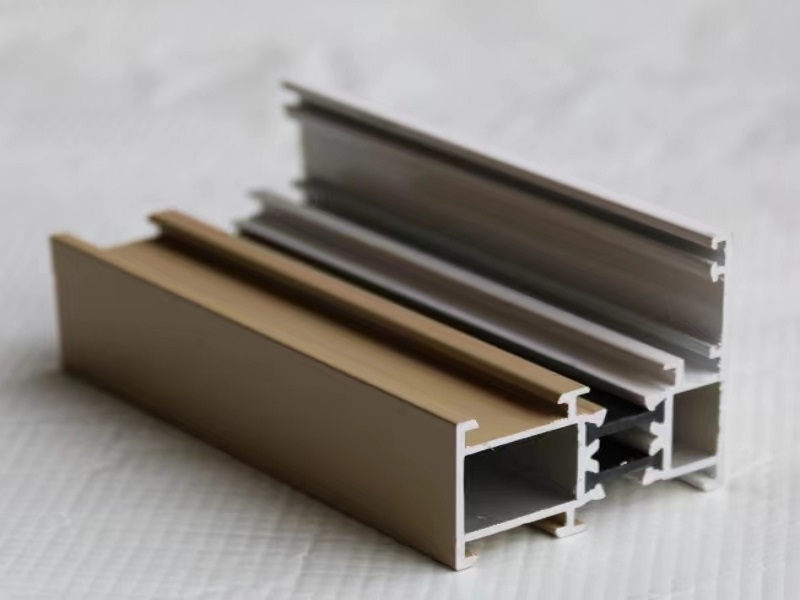

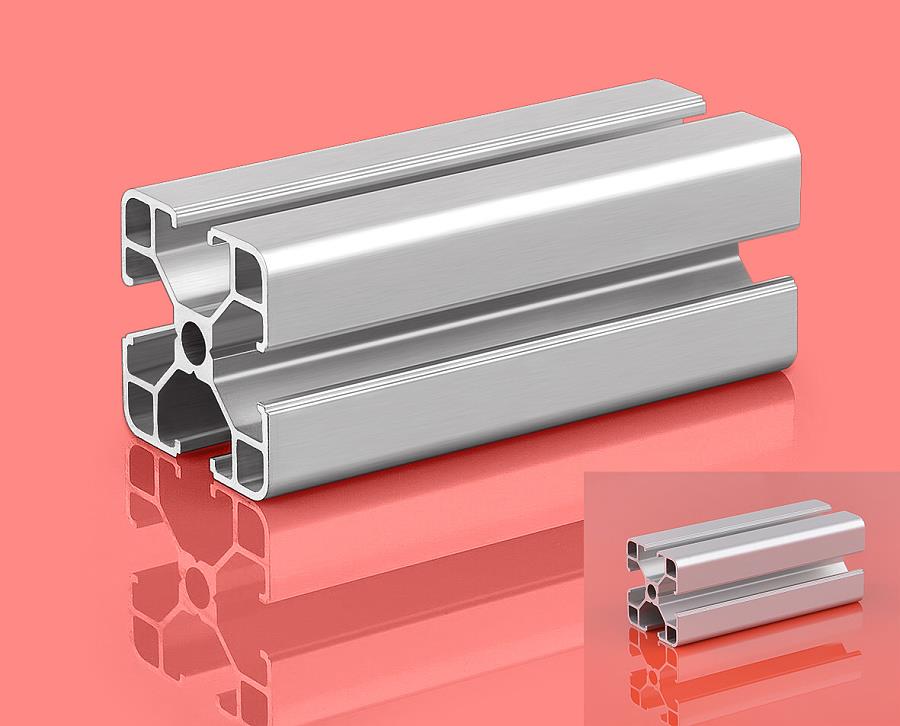

The 6XXX series was created for aluminium alloys of magnesium and silicon. These alloys are excellent candidates for anodic oxidation. The oxide layer following the anodic oxidation process is transparent and provides excellent protection. Because of their excellent mechanical properties and ease of anodizing, the 6XXX series alloys are frequently used for structural applications.

This series of alloys uses zinc as its main alloying element. It is well suited to the anodic oxidation process. The subsequent oxide layer is transparent and provides good protection. If the zinc content is too high, the oxide layer produced by the anodic oxidation will turn brown.

For Further Details,Please Feel Free To Contact Us: