Abstract: composites have many significant advantages in the application of construction engineering. For example, they can obtain high-precision complex shapes, have good resistance to degradation, and have strong corrosion resistance.

1. Inorganic and organic materials

Glass fiber reinforced plastics, polymer concrete, asphalt concrete, etc.

2. Non metallic and metallic materials

Reinforced concrete, steel wire mesh cement, plastic aluminum composite pipe, aluminum foil faced linoleum, etc.

3. Other composites

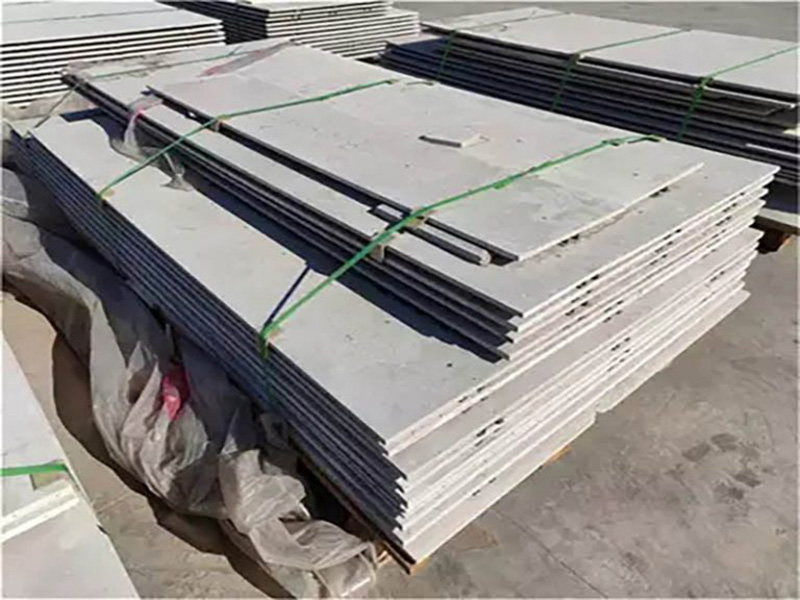

Cement asbestos products, stainless steel clad steel plate, etc.

Building composite materialsThey offer new aesthetic possibilities because of their ability to shape complex, smooth and creative shapes, as well as the ability to integrate special surface treatments and a wide range of effects, including the simulation of traditional materials.

Building composite materialsComposite Materials do not oxidize or corrode. There are many polymer matrix systems that provide long-term resistance in most temperature and chemical environments. Compared with traditional building materials, composite components with reasonable design have longer service life and minimum maintenance.

Building composite materialsComposite Materials have higher resistivity than most materials used in similar applications, which provide more gravity than most metal alloys.

Building composite materialsHow long can composite Materials last? There is a duration reference of more than 50 years. Polymer matrix composites are relative to the materials they usually replace, such as concrete and steel

Iron and wood are relatively new, so their “life expectancy” has not been applied in many composites.

Building composite materialsComposite materials can be realized in almost any shape: it may have complex structure; It may be large or small, structured, decorated, or even a combination of them. Composite materials enable architects and designers to try new concepts, from prototype to production.

In view of this flexibility, a single component of the composite materials can replace complex units that require many fixed elements, which are made of traditional materials such as wood, steel and aluminum.

Building composite materialsMaterials formed from FRP maintain their shape and function even under severe mechanical and environmental pressures.

Polymer matrix composite materials have excellent electrical insulation properties.

Components made of polymer matrix and suitable filler have very good performance in high temperature applications.

There are three different kinds of polymer concrete, such as polymer impregnated concrete. After the polymer infiltrates into the internal pores of the concrete, the compactness of the concrete is improved.

It can be used in special document projects requiring high strength and high durability, such as high-pressure gas transmission pipeline, high-pressure infusion pipe, high-pressure container, marine structure, atomic energy reactor and other projects.

5. Cermet, metallic glass, etc.

According to the process principle, pattern steel can be divided into the following common categories:

For Further Details,Please Feel Free To Contact Us: