There are three main classifications of aluminum

Rolled products, cast products, rolled products

Non-heat treatment type alloy, pure aluminium alloy (1××× series), aluminium-copper alloy (2××× series), aluminium-manganese alloy (3××× series), aluminium-silicon alloy (4××× series), aluminium-magnesium alloy (5××× series), aluminium-magnesium-silicon alloy (6××× series), aluminium-zinc-magnesium alloy (7××× series), aluminium and other elements alloy (8××× series).

Casting, heat-treated alloys, non-heat-treated alloys.

Rolled products: Sheet, Plate, Coil, Strip.

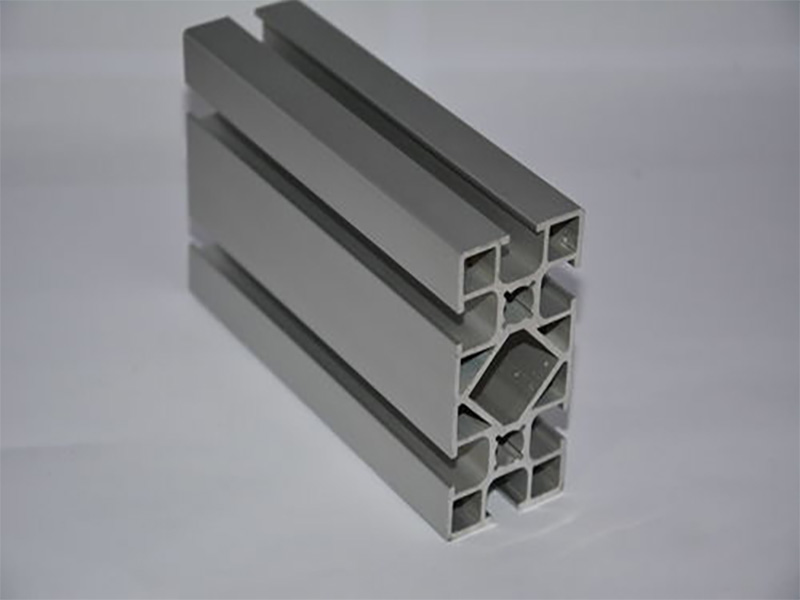

Extruded products: Tubes, solid bars, profiles.

Casting products: Castings.

The formula for calculating the weight of aluminium is as follows

Weight of square aluminium bar (kg) = 0.0000027 x side width x side width x length

Weight of square copper bar (kg) = 0.0000089 x side width x side width x length

Weight of square brass bar (kg) = 0.0000085 x side width x side width x length

Aluminium patterned sheet: weight per square metre = 2.96*thickness

Weight of aluminium tube (kg) = 0.00000879 x wall thickness x (OD – wall thickness) x length

Weight of aluminium sheet (kg) = 0.0000027×thickness×width×length

Classification of aluminum

Consumers should pay attention to the following points when purchasing and using aluminum alloy building profile products.

For Further Details,Please Feel Free To Contact Us: