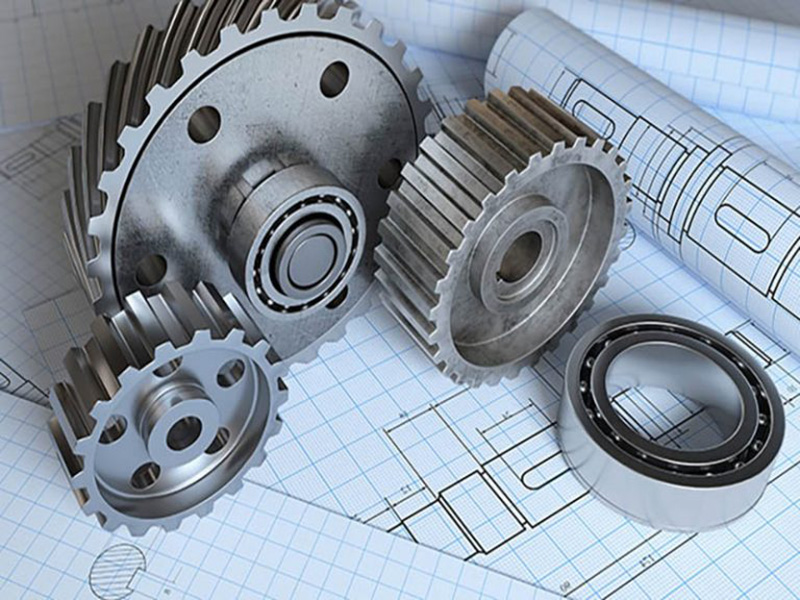

1、Gear steel and gears are steels that can be used for processing and manufacturing gears

Any steel that can be used to process gears can be called gear steel. As gears rely on their own structural dimensions and material strength to withstand external loads, the steel used to manufacture gears is required to have high strength, hardness, toughness, wear resistance and manufacturability.

With the development of science and technology, is towards high performance, long life, smooth running gears, low noise, safety, low cost, easy processing, multi-species direction.

2、Performance indicators

In terms of performance indicators, the main criteria for measuring the performance of gear steel are three.

(1). Hardenability

Mainly to ensure the hardness of the heart of different sizes of gears, conducive to the control of heat treatment deformation of gears. Its performance mainly depends on the chemical composition and its uniformity.

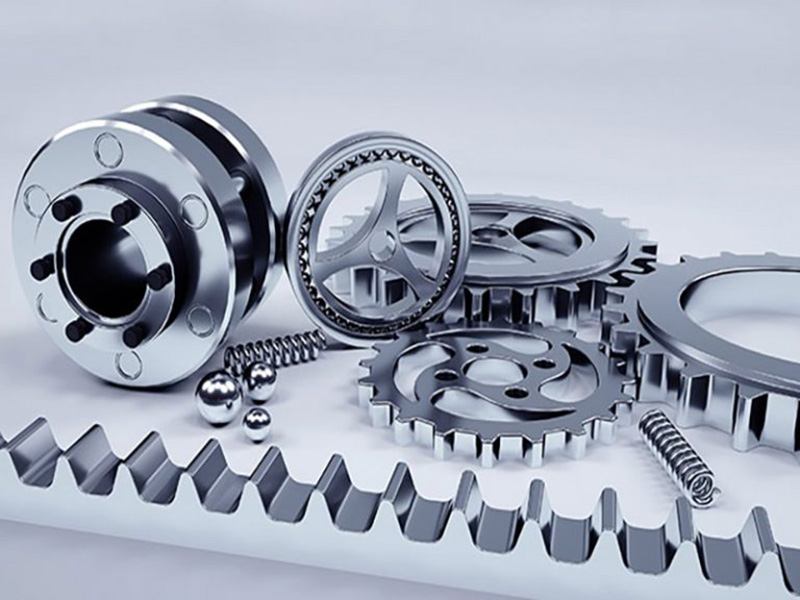

Classification of gears according to their axial characteristics

1, parallel axis gears: spur gears, helical gears, internal gears, rack and pinion gears, etc.

2、Intersecting axis gears: spur gears, spiral bevel gears, zero teeth, bevel gears, conical gears, etc.

3、Intersecting shaft gears: intersecting shaft helical gears, worm gears, hypoid gears, etc.

4、Special axis gears: planar gears, harmonic gears, cycloidal gears, etc.

For Further Details,Please Feel Free To Contact Us: