Steel plate waterstop, also known as metal plate waterstop, water-stop steel plate, is a common waterproof material in engineering, including steel plate, copper plate, alloy steel plate, etc., mainly used for reinforced concrete junction, dams and other large projects, using metal plate waterstop, can change the path of water penetration, extend the route of water penetration, in the leakage of water may contain corrosive components of the construction environment, metal plate waterstop can play a certain anti-corrosion effect . In the protection project, the use of metal plate water stops can ensure the protection effect of the project. Metal plate waterstop is also commonly used in projects with high seepage resistance requirements and small areas, such as casting pits in smelters, electric furnace pits, etc.

Water-stop steel plate belt is mainly used for reinforced concrete water-stop steel plate structure, dams and other large projects. Such as: tunnels, subways, dams, culverts, construction joints in water conservancy and hydropower projects, basements of high-rise buildings, underground parking lots and other major projects construction joints. Steel plate waterstop has an important role in infrastructure projects, underground facilities, tunnels, sewage treatment plants, water conservancy, subway and other projects.

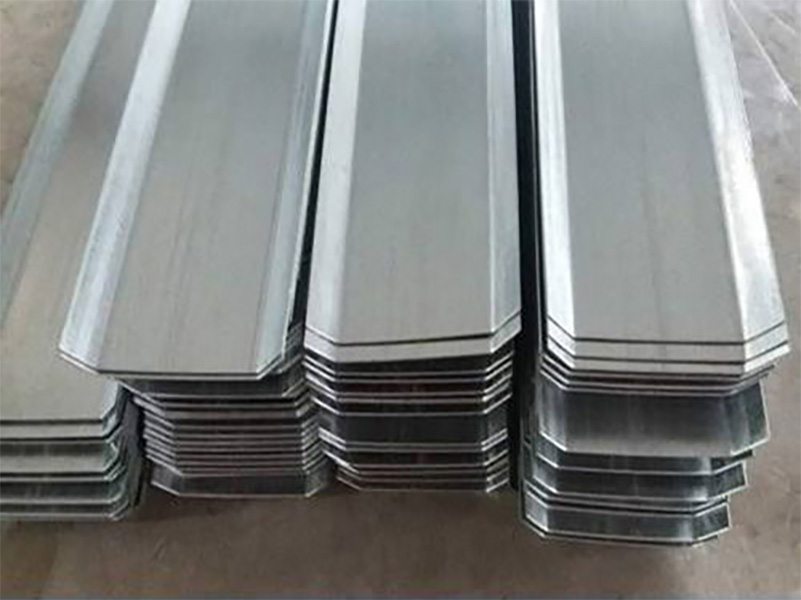

water-stop Steel plate products, also known as water-stop steel plate, can be mainly divided into: ordinary steel plate waterstop, galvanized steel plate waterstop, stainless steel plate waterstop, specifications for.

200×2, 200×3, 300×2, 300×3, 350×2, 350×3, 400×4, 330×5 and other specifications. The length is 3 meters, and can be customized according to user requirements.

Usually for the convenience of operation processing into ≤ 2m per section, construction should pay attention to lap, weld surface should pay attention to welding, the corner should be handled reasonably, and the good steel plate water stop

Should be fixed firmly with the reinforcement of the wall (or plate). Steel plate should be straight and not twisted. Such as the use of steel plate water stop in the construction of horizontal joints should be careful.

Construction joints in tunnels, subways, dams, culverts, water conservancy and hydropower projects, basements of high-rise buildings, underground parking lots and other major projects.

1. Water-stop steel plate: the weld must be full, without slag inclusion, and the weld height can meet the requirements; No trachoma, no burn or edge bite in the weld; There is no deformation or warpage of the joint steel plate, and the position and elevation of the water-stop steel plate are correct.

2. Check the appearance quality of the water-stop steel plate after the material comes into play, and return or cut off the section that does not meet the requirements.

1、Do not touch or move the water-stop steel plate when tying the reinforcement and installing the formwork.

2、Check the position and appearance of the water-stop steel plate again before the formwork is closed, and find problems in time.

Timely processing.

1, the operator must be licensed to work, enter the site must wear a helmet.

2, the electric welding machine must be double line in place, the primary line length shall not be greater than 15m, the secondary line shall not be greater than 5m, shall not borrow steel as ground, welding machine wiring must have a full-time electrician wiring.

3, welding should wear a good welding cap, protective gloves.

4, every day before the end of the day, should be used to machine, tool recycling into storage, the work surface within the debris cleaned up, to live after the material net.

5, when welding is strictly prohibited to use water to cool the weld, such as in case of rain should take measures to shield

For Further Details,Please Feel Free To Contact Us: