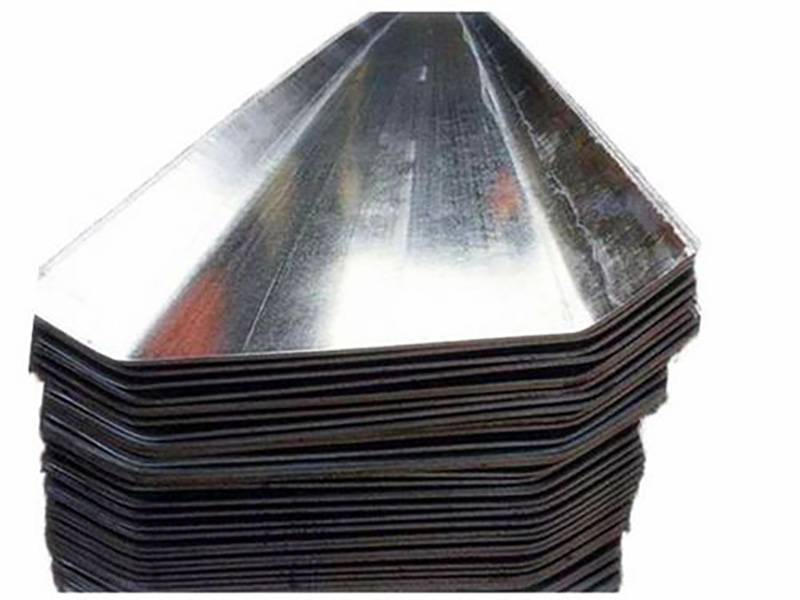

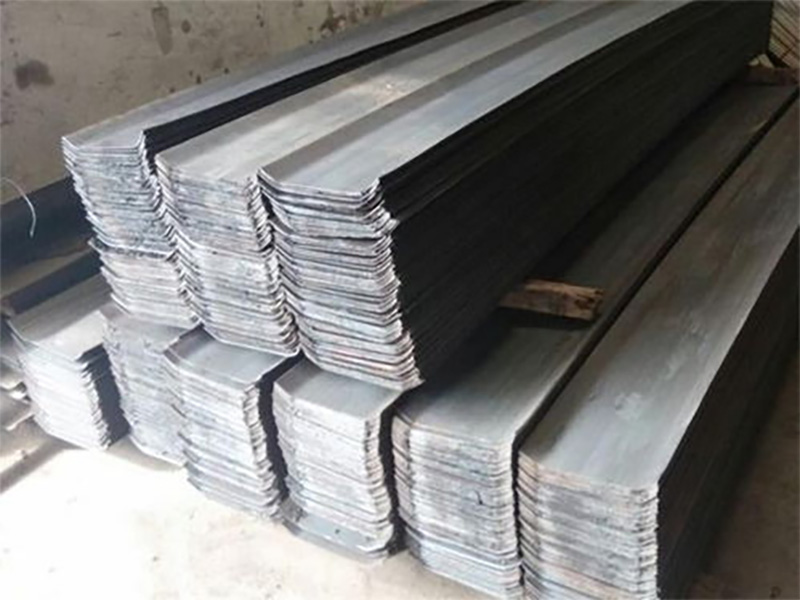

3mm thick formed waterstop steel plate, single length 6000mm, width 300mm, material Q235B, processed into the shape required by the drawing before use, no oil or rust on the surface of the plate. E43 welding rod, diameter Φ2.0 (should be dried before use), Φ10 fixing bar, electric welder.

Welding machine, welding cap, welding hammer.

1 welder and 1 general worker.

Waterstop steel plate positioning → fixing → joint welding → shear wall lacing and positioning steel bar welding → inspection and acceptance.

Concrete location of waterstop steel plate for horizontal construction joint of foundation: the central elevation of waterstop steel plate is 300mm above the top elevation of equipment foundation bottom plate. All waterstop steel plates should be placed in the middle of the shear wall and arranged along the circumference of the shear wall. The vertical setting and each horizontal waterstop steel plate are welded tightly in a circle.

After the position of the waterstop steel plate is determined, temporarily clamp and fix it up and down with the wall hook bar, and then weld the steel plate seam.

The lap length of waterstop steel plate is 50mm. The welding of steel plate should be divided into two times, and 2mm weld seam should be left at the joint. When welding for the first time, spot welding should be carried out at the middle and both ends, then welding from the middle to the upper end, and then welding from the lower end to the middle. Immediately after the first time, the coating should be knocked off with a welding hammer to check whether there are sand holes or missing welds, and repair welding should be carried out if any. The second pass should be welded from the lower end. T-shaped welding or 7-shaped welding is used at the corner of shear wall. Double side welding. The following figure:

Along the direction of the waterstop steel plate, φ 10 steel bars are used for welding on both sides; One end is welded on the waterstop steel plate, and the other end is welded on the horizontal and vertical main reinforcement of the shear wall to position it; The spacing of positioning reinforcing bars is 1000mm, and both sides are symmetrically arranged.

Due to the small spacing of shear wall lacing bars, the middle total lacing bar passes through the water-stop steel plate. After the seam of the water-stop steel plate is welded, the lacing bar is cut off at the lacing bar passing through the water-stop steel plate, and then welded on the water-stop steel plate.

After the waterstop steel plate is welded, self-inspection should be conducted to check whether there is any trachoma, broken welding, missing welding or incomplete welding seam, and rework should be done if it does not meet the requirements. Whether the positioning reinforcement is firmly welded; Whether additional lacing is added or not, if not, it will be re-welded or added. After passing the inspection, report to the supervision engineer for inspection and acceptance.

(1) The horizontal construction joint of the wall should not be left at the intersection of the shear wall and the maximum moment or the base plate and the side wall, and should be left on the wall 500mm above the surface of the base plate (design requirements); when there are reserved holes on the wall, the construction joint should not be less than 300mm from the edge of the hole.

(2) After determining the horizontal elevation of the steel plate waterstop, draw a line according to the elevation control point of the building in order to keep the upper opening of the steel plate waterstop straight.

(3) under the steel plate waterstop welding short reinforcement, play a supporting role to prevent sinking, the length of the short reinforcement should be subject to the thickness of the concrete slab wall reinforcement mesh, not too long to prevent the formation of water seepage channel along the short reinforcement, the center of the short reinforcement should be welded water ring, to block the seepage route.

(4) short reinforcement spacing of about 1 per 800mm, so that it is large to meet the residential building open space size. The spacing should not be too small, otherwise it will increase the cost and workload, the spacing is too large, the steel plate waterstop easy to bend, especially when pouring concrete by vibration, easy to produce deformation.

(5) for the steel plate water stops through the L-shaped, rectangular and corner column often cross with the column hoop, need to do the details of processing. To be agreed by the design, the scope of the steel plate waterstop column hoop interrupted and welded with the steel plate waterstop, construction should strengthen the tracking check to prevent welding through the steel plate, construction should be completed in time to clean up the welding slag.

After the installation of the steel plate waterstop, in order to prevent the concrete vibrating when the steel plate in the plate wall inside and outside shaking, but also in the appropriate location with short reinforcement and plate wall main reinforcement welding, its spacing is 400mm, and high and low alternating arrangement, in order to prevent the steel plate waterstop to one side of the tilt, to ensure that the height of the steel plate waterstop half of the upper and lower.

(1) in the concrete pouring, because the steel plate waterstop will be the concrete at the plate wall is divided into two, the space on both sides is small, so the construction here should pay special attention to arrange special people will steel plate waterstop both sides of the concrete at the same time cast, while using the diameter φ30mm vibrating rod vibrating compact, to ensure that the steel plate waterstop waterstop effect, and timely moisturizing maintenance.

(2) before pouring the upper concrete slab wall, the steel plate waterstop and horizontal construction joint surface floating slurry and debris clean, first laying net slurry, and then laying 30 ~ 50mm thick 1:1 cement mortar or brush concrete interface treatment agent and timely pouring of concrete, so that the old and new concrete bonding solid, to ensure that the steel plate waterstop water effect.

For Further Details,Please Feel Free To Contact Us: