Strength is an important quality in the use of metals. This is especially true in construction, transportation, heavy industry and tool manufacturing. Metal alloys are usually stronger than pure metals. When discussing the strongest metal, we should first consider what strength is.

There are many methods for measuring metal strength:

Yield strength measures the minimum stress that causes permanent deformation.

Compressive strength measures the amount of compressive stress that causes defects.

Tensile strength measures the amount of tensile stress that causes defects.

Impact strength measures the impact energy that causes fracture.

The importance of different types of strength depends on the intended use of the metal.

There are many metals that can be considered “the strongest”. Of course, much depends on the use of the metal. Another consideration is the various alloys that each metal can form.

In other words, four metals are the strongest: steel, titanium, tungsten and Inconel.

Steel is an alloy of iron and carbon, usually combined with other elements. It is made by heating iron ore in a furnace, removing impurities and adding carbon. Pig iron has toughness and weak strength, but the addition of other elements such as manganese, niobium or vanadium makes the steel have strength and hardness. However, it is important to remember that these additional elements also affect other properties such as toughness and ductility.

Steel is one of the most common materials in the modern world, producing more than 1.3 billion tons of steel every year. It is widely used in transportation, infrastructure, construction and weapons industry. Most large modern buildings – including skyscrapers, airports and bridges – are supported by steel structures. In the automotive industry, steel is still the main material, although aluminum is becoming more and more popular. Steel is also used for smaller items such as screws, nails, and kitchen utensils.

Stainless steel is a corrosion resistant alloy containing at least 11% chromium.

Tool steels are made of tungsten and cobalt alloys and are known for their hardness. Tool steel maintains a sharp cutting edge for shafts and drills.

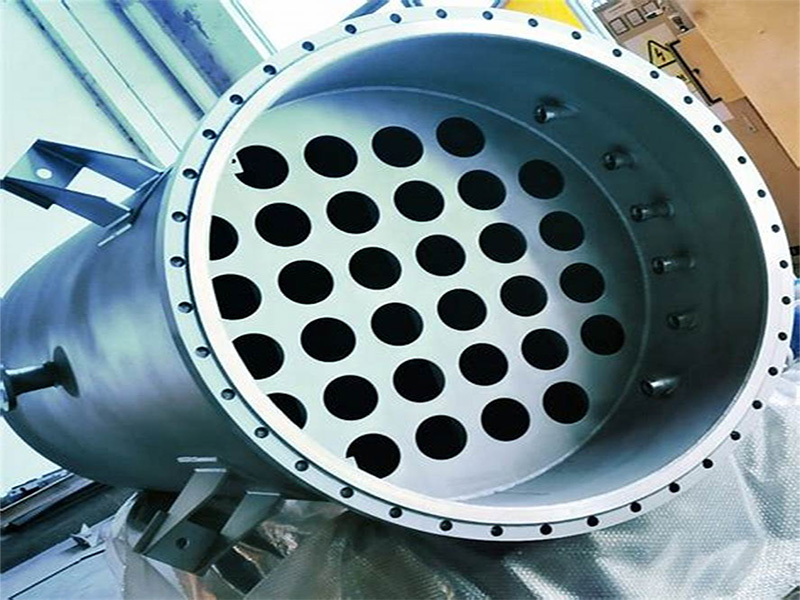

Maraging steels are alloyed with nickel and other elements. It has low carbon content and high strength. Maraging steels are used in rocket and missile shells, uranium enrichment gas centrifuges and sword blades.

Titanium is a silver plated metal with low density and high strength. It is worth noting that it has the highest tensile strength density ratio of any metal element. However, it is not as hard as some kinds of heat-treated steel.

Titanium is usually alloyed with a series of elements such as iron, aluminum and vanadium. Titanium alloy has high strength and light weight. It is an ideal material for automotive, aerospace, military and industrial applications. Two thirds of the titanium produced is used for aircraft parts. Titanium also has strong seawater corrosion resistance, which makes it very suitable for propeller shafts, rigging and diving knives.

Tungsten is a rare metal that exists on the earth in the form of compounds. It is metallic gray, fragile and difficult to process. If refined to the purest form, it is harder than most steels. Among all pure metals, tungsten has the highest melting point, the lowest vapor pressure and the highest tensile strength. Its coefficient of thermal expansion is the lowest of all pure metals.

After tungsten and steel are alloyed, the toughness is greatly enhanced.

About half of tungsten is used in the production of hard materials, mainly tungsten carbide. Tungsten carbide is used to make cutting tools, drill bits, circular saws and lathes. The metal processing, mining, construction and petroleum industries rely heavily on tungsten carbide tools. Tungsten is also used to make alloys. The high melting point of tungsten makes it an ideal material for rockets and missiles.

Inconel is a high-temperature alloy made of austenite, nickel and chromium. It is characterized by high strength and will not weaken under high temperature. It also has a high degree of oxidation and corrosion resistance.

The properties of Inconel make it suitable for use in extreme environments. It is usually used in gas turbine blades, well pump motor shafts, chemical treatment plants and nuclear pressurized water reactors.

For Further Details,Please Feel Free To Contact Us: