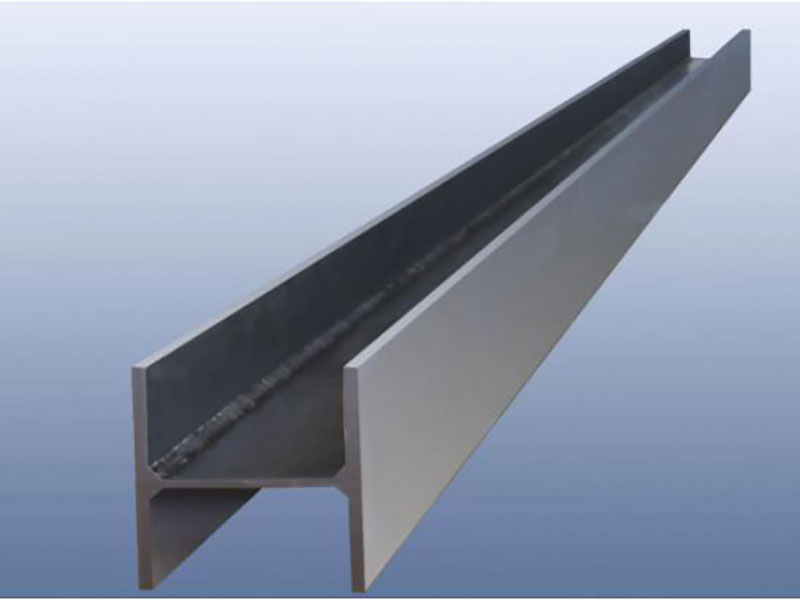

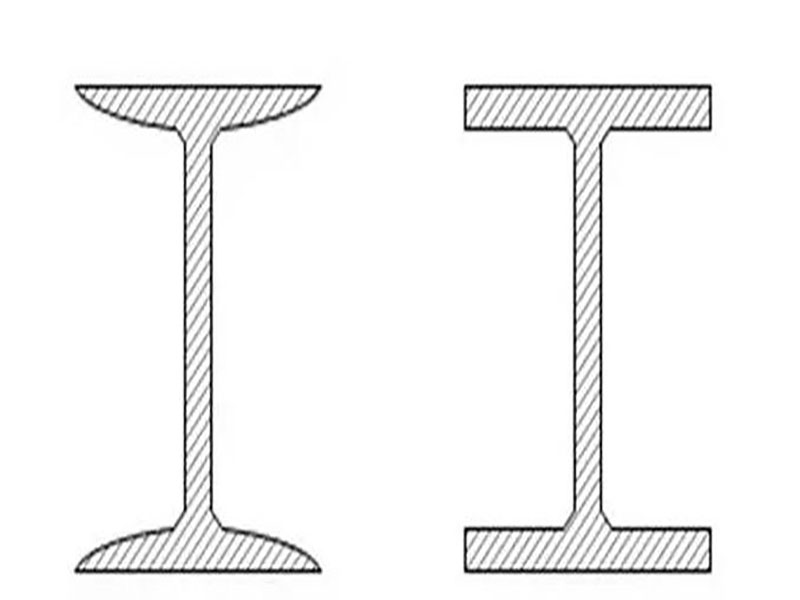

H-beam steel is a kind of economical section and high-efficiency section with more optimized cross-sectional area distribution and more reasonable strength-to-weight ratio. It is named because its section is the same as the English letter “H”. Since the various parts of the H-shaped steel are arranged at right angles, the H-shaped steel has the advantages of strong bending resistance, simple construction, cost saving and light structure weight in all directions, and has been widely used.

◆High structural strength: Compared with I-beam, the section modulus is larger, and the metal can be saved by 10-15% when the load-bearing conditions are the same.

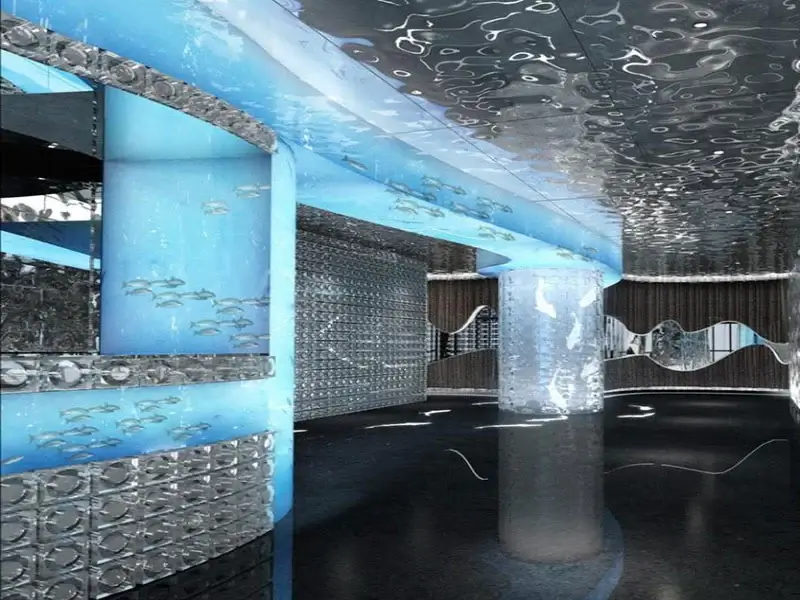

◆The design style is flexible and rich: in the case of the same beam height, the steel structure bay can be 50% larger than the concrete structure bay, so that the building layout is more flexible.

◆Light structure weight: Compared with the weight of the concrete structure, the weight of the structure is reduced, which reduces the internal force of structure design, which can reduce the requirement of building structure foundation treatment, the construction is simple, and the cost is reduced.

◆High structural stability: The steel structure mainly made of hot-rolled H-section steel has a scientific and reasonable structure, good plasticity and flexibility, and high structural stability. It is suitable for building structures that withstand large vibration and impact loads, and has strong resistance to natural disasters. , Especially suitable for some building structures with many earthquake occurrence zones. According to statistics, in the world’s devastating earthquake disasters of magnitude 7 or above, steel structures dominated by H-shaped steel have suffered the least damage.

◆Increase the effective use area of the structure: Compared with the concrete structure, the steel structure column has a small cross-sectional area, which can increase the effective use area of the building. Depending on the different forms of the building, it can increase the effective use area by 4-6%.

◆Saving labor and materials: Compared with welding H-shaped steel, it can significantly save labor and materials, reduce the consumption of raw materials, energy, and labor, low residual stress, and good appearance and surface quality.

◆Easy for mechanical processing: easy to connect and install the structure, and easy to dismantle and reuse.

◆Environmental protection: The use of H-shaped steel can effectively protect the environment, specifically in three aspects: First, compared with concrete, dry construction can be used, resulting in less noise and less dust; second, due to the reduced weight and the amount of soil taken for foundation construction Less damage to land resources. In addition, a large reduction in the amount of concrete and a reduction in the amount of excavation and stone excavation are conducive to the protection of the ecological environment; third, after the service life of the building structure expires, the amount of solid waste generated after the structure is demolished is small, and the scrap steel resources High recycling value.

◆The high degree of industrialized production: The steel structure mainly made of hot-rolled H-beam has a high degree of industrialized production, which is convenient for mechanical manufacturing, intensive production, high precision, convenient installation, and easy to ensure quality. It can be built into a real house manufacturing factory and bridge manufacturing factory, Industrial plant production factories, etc. The development of steel structures has created and promoted the development of hundreds of emerging industries.

◆Fast construction speed: small footprint, suitable for all-weather construction, and less affected by climatic conditions. The construction speed of steel structures made of hot-rolled H-section steel is about 2-3 times that of concrete structures, and the capital turnover rate is doubled, which reduces financial costs and saves investment.

H-beam steel is mainly used for beam and column members in industrial and civil structures.

◆Steel structure load-bearing support for industrial structures

◆Steel piles and supporting structure of underground engineering

◆The structure of industrial equipment such as petrochemical industry and electric power

◆Long-span steel bridge components

◆The frame structure of ship and machinery manufacturing

◆Girder brackets for trains, cars, and tractors

◆Port conveyor belt, high-speed baffle bracket

For Further Details,Please Feel Free To Contact Us: