Carbon Steel Sheet

Carbon steel sheet is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%. It is also called carbon steel sheet. Generally, it also contains small amounts of silicon, manganese, sulfur and phosphorus. Generally speaking, the higher the carbon content of carbon steel sheet, the harder and stronger it is.

DC06 Cold Rolled Sheet

DC06 Cold Rolled Sheet It is a flat sheet of steel that is poured with molten steel and pressed after cooling. It is flat, rectangular and

NM500 Wear-Resistant Steel Plate

NM500 Wear-Resistant Steel Plate Bimetal composite wear-resisting steel plate is composed of low carbon steel plate and alloy wear-resisting layer. The wear-resisting layer generally accounts for

Cold Rolled Steel Plate

Cold Rolled Steel Plate Cold Rolled Steel Plate is a flat sheet of steel that is poured with molten steel and pressed after cooling. Cold Rolled

Specifications of Carbon Steel Sheet

| Product Name: | Carbon Steel Sheet |

| Place of Origin: | Shandong, China |

| Standard: | Aisi, ASTM, bs, DIN, GB, JIS,etc |

| Material: | Q235B,Q355B,Q235-A·F, 20, 45, 60, 40Mn, 65Mn, 08F, T7-13 ZG200-400 |

| Thickness: | 0.1-3mm, or as customer’s requirements |

| Width: | 1000mm, 1220mm, 1250mm, 1500mm, 2000mm according to customer’s requirement |

| Length: | any length as required |

| Processing Service: | Bending, Welding, Cutting |

| Tolerance: | ±1% |

| Packaging : | export standard package or as request |

| Terms of price: | FOB, CIF, CFR, EXW |

| Payment terms: | TT, Irrevocable LC at sight, Western union, Ali trade assurance |

Product Show of Carbon Steel Sheet

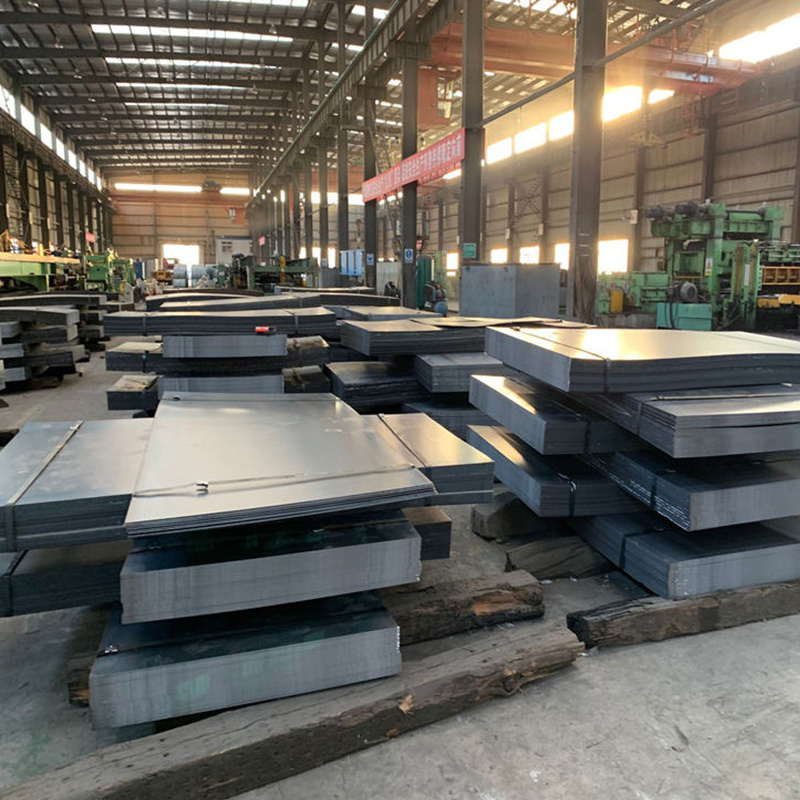

Factory Show of Carbon Steel Sheet

Application of Carbon Steel Sheet

1. Cold rolled strips are used for a wide range of applications, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, food cans, etc.

2. The uses of hot rolled steel.

- Structural steel plate. Mainly used in the production of steel structural plates, bridges, ships, vehicles, etc.

- Weathering steel: Used in the production of containers and special vehicles, also used in building structures.

- Automotive structural steel plate: high strength steel plate with good stamping performance and welding performance, used for the production of automotive FRAME, WHEEL, etc.

- Hot-rolled special steel plates: used for the production of various mechanical parts.

- Cold-rolled raw plates; used for the production of various cold-rolled products, including CR, GI, color coated plates, etc.

FAQ

- Carbon steel sheet can be divided into three kinds of carbon structural steel sheet, carbon tool steel sheet and free-cutting structural steel sheet according to its usage. Carbon structural steel sheet can be further divided into steel sheet for engineering and construction and structural steel for machinery manufacturing.

- According to the smelting method, it can be divided into open hearth steel plate and converter steel plate.

- According to the method of deoxidation, it can be divided into boiling steel (F), killing steel (Z), semi-killing steel (b) and special killing steel (TZ).

- Carbon steel sheets can be divided into low carbon steel sheets (WC≤0.25%), medium carbon steel sheets (WC0.25%-0.6%) and high carbon steel sheets (WC>0.6%) according to the carbon content.

- According to the quality of steel sheet, carbon steel sheet can be divided into ordinary carbon steel sheet (higher phosphorus and sulfur content), high quality carbon steel sheet (lower phosphorus and sulfur content) and high grade high quality steel sheet (lower phosphorus and sulfur content). As well as super premium steel sheets.

Manganese

About 0.25%~0.80%. Solid solution strengthening; remove FeO, reduce the brittleness of steel sheet; sulfide synthesis MnS, can reduce the harmful effect of sulfur. Useful.

Silicon

About 0.10%~0.40%, solid solution strengthening; useful to eliminate the adverse effect of FeO on the quality of steel plate.

Sulfur

FeS forms low-melting eutectic with Fe (melting point is 985℃), which makes the steel plate brittle and cracking during hot working at 1000~1250℃, i.e. “hot brittleness”. Harmful.

Phosphorus

Strength and hardness are improved, but plasticity and toughness are reduced, “cold brittleness”. Harmful.

Carbon structural steel sheet

Grade: Example Q235-A-F, i.e. σs=235MPa. Brand notes. Q is yield strength A quality grade (there are four grades of ABCD), F is boiling steel.

Features: Low price, excellent process properties (such as weldability and cold formability).

High quality carbon structural steel sheet

Species. Example 45, 65Mn, 08F.

Brand description: directly indicates the parts per million of carbon content in the metal.

Grade. Example: T12 steel plate indicates carbon tool steel with Wc=1.2%.

Brand description: T plus parts per thousand of the carbon content of the metal.

Features. It is eutectic and super eutectic steel plate with high strength, high hardness and good wear resistance. It is suitable for manufacturing various low-speed cutting tools.

Common steel plate grades and uses.

T7, T8: Used in the manufacture of parts that can withstand certain impact and require toughness. Such as sledgehammer, punch, chisel, woodworking tools, scissors.

T9, T10, T11: Manufacturing tools that require high hardness and high abrasion resistance, with less impact. Such as taps, small drills, dies, hand saw blades.

T12, T13: Manufacture tools that are not resistant to impact. Such as files, scrapers, razors, measuring tools.

Cast steel pieces

Grade. For example, ZG200-400, which means

Cast steel sheet with σs=200MPa and σb=400MPa.

Performance. Casting properties are worse than cast iron, but mechanical properties are better than cast iron.